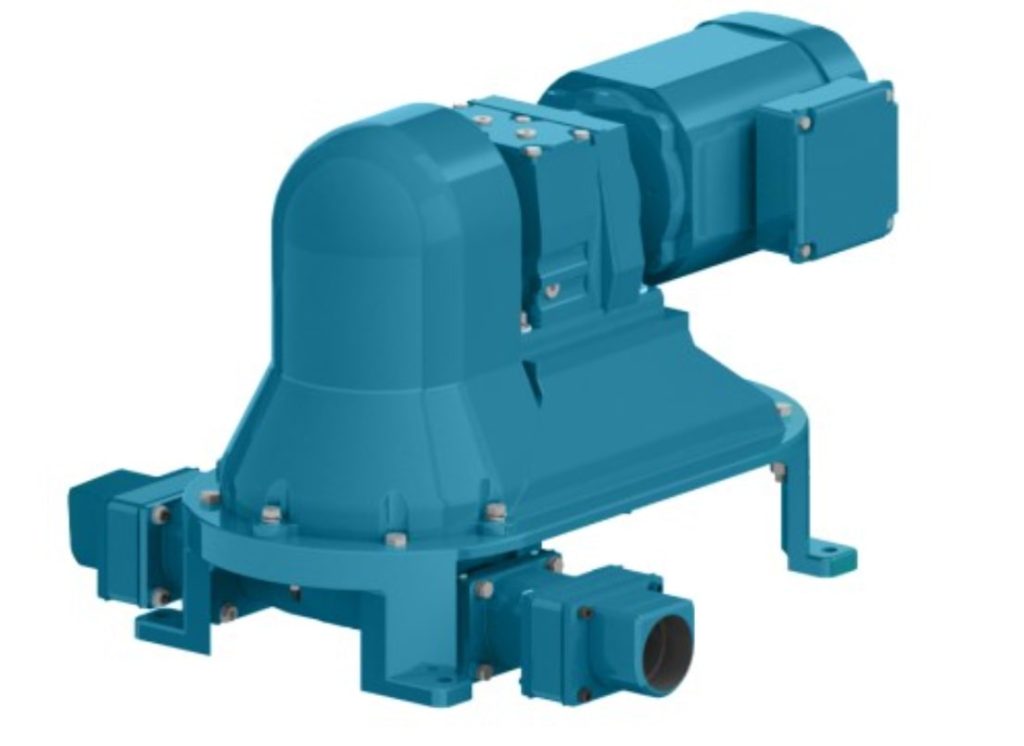

Wastecorp didn’t invent the diaphragm pump but when we introduced the Mud Sucker diaphragm pump product line almost 25 years ago we set out to innovate and radically transform how customers transfer fluids. One of our first Mud Sucker models, the 4BW-MDD Series is a walking beam style pump that uses a heavy duty piston motion to move heavier slurries found in coal mine, pulp and paper and municipal sewage applications. What makes this pump so special is its ability to transfer heavy solids with a choice of Siemens gear box and motor, gas or diesel engine (Yanmar diesel model shown).

Driving the Conversation in The Diaphragm Pump Business

The variety of pumping applications we see from the field grows everyday; From biodiesel production, bauxite, sugar refining to refineries and waste water treatment. And, each of these applications gets improved pumping performance with different components designed for specific applications. With Wastecorp’s flex-production floor, pump models like the 4BW-MDD can get stainless steel valve seats for customers who move corrosive fluids or FDA compliant internal coatings for customers in the food processing industry.

Wastecorp’s improved production efficiency gets translated into cost savings for the pump user in a variety of ways.

First, you get the pump you need without having to overkill your pump purchase with the traditional cookie cutter approach to pump sales – “this is what we offer, take it or leave it.” Thankfully you no longer need to settle for any pump. Our technical support engineers offer suggestions for your pump based on field tests in your industry and current user feedback (contact Wastecorp). Second, with a flex-production floor, the waiting time for your pump is drastically reduced; Mud Sucker pumps are manufactured close to your region for quicker delivery, service and support.

When considering your trash pump or diaphragm pump purchase remember that the pump should be designed for your application not the other way around. Your diaphragm pump manufacturer should also be ISO 9001 certified and adhere to Hydraulic Institute standards.