In a world of increasing water scarcity, wastewater management has become crucial to limiting the adverse effects of climate change and population growth. Purifying wastewater allows us to conserve the planet’s freshwater resources, safeguarding ecosystems, agriculture, and the 40% of the human population currently affected by water scarcity. Wastewater treatment also protects us from disease by preventing the contamination of drinking water supplies.

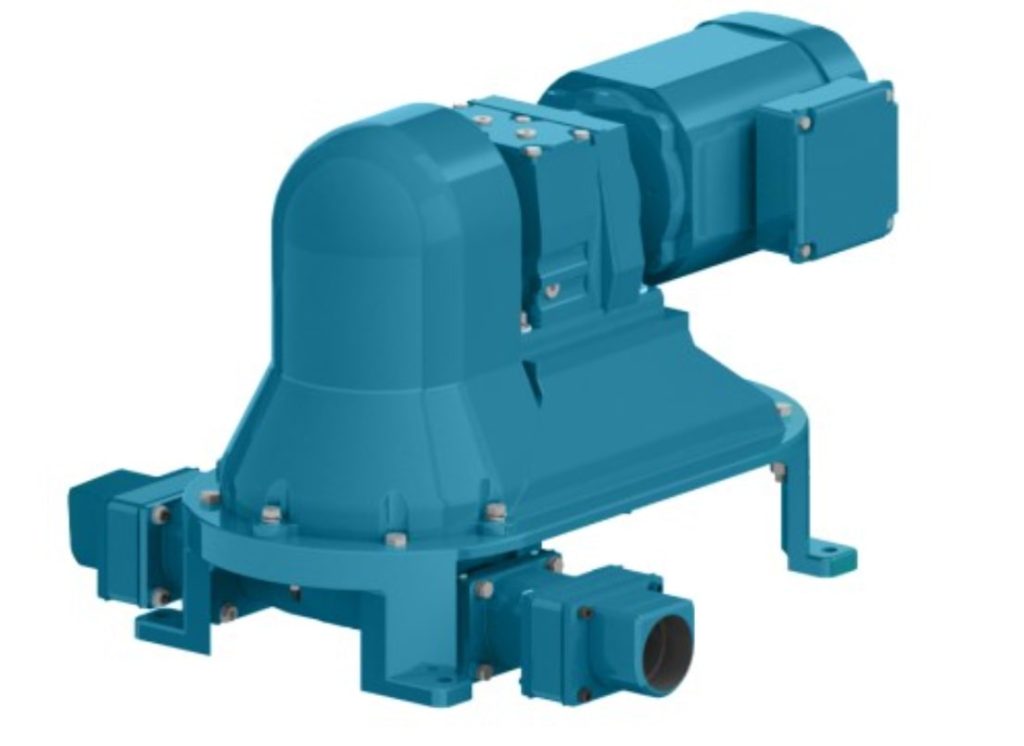

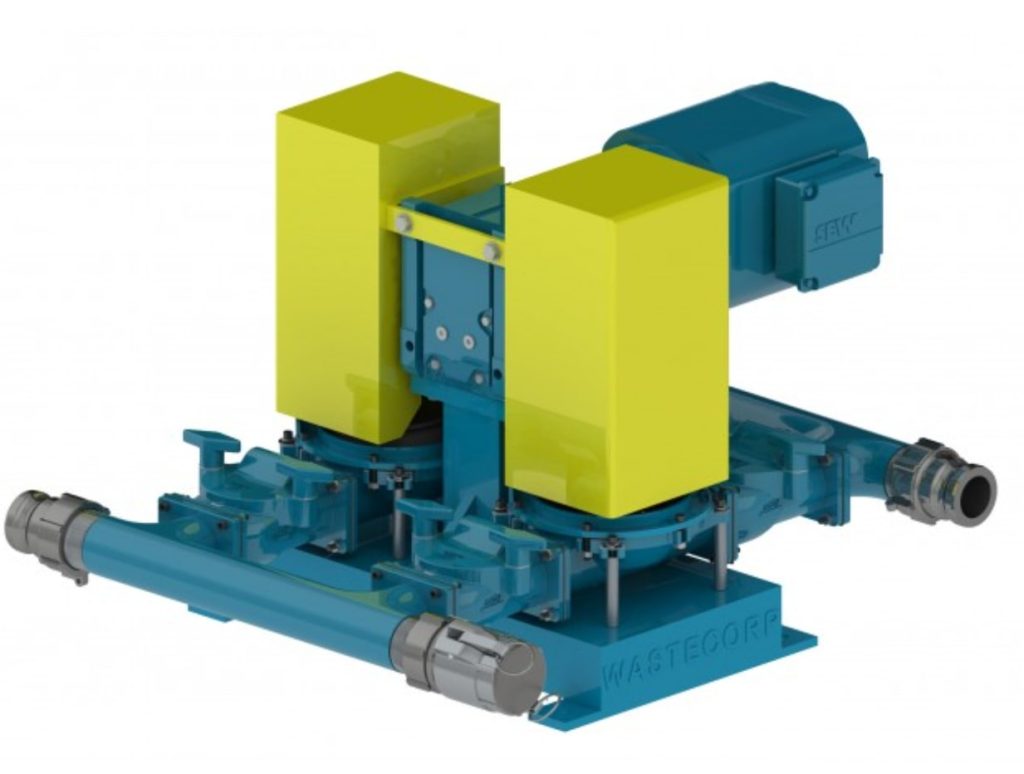

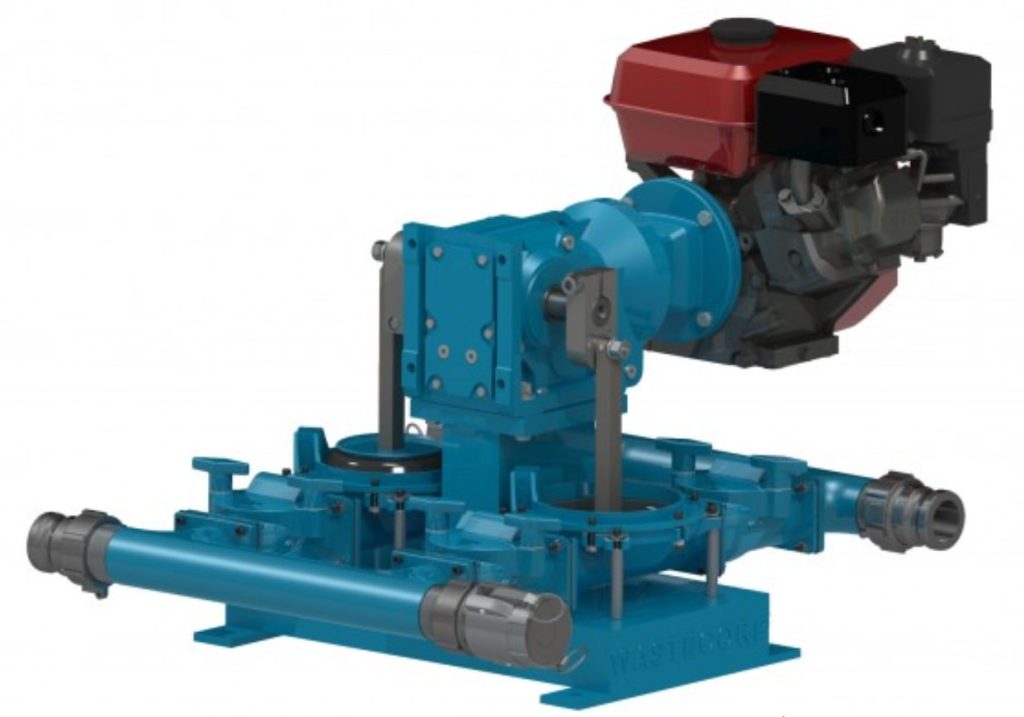

Understanding the critical role that wastewater industries play in managing the health of society and the environment was a key motivator for Wastecorp’s founders. Our Mudsucker line of diaphragm pumps is designed to protect lakes, rivers, and streams by transporting effluent without leaking or clogging. Their long service life and ease of maintenance also helps keep wastewater management affordable and accessible for everyone.

Below, we’ll explain why our diaphragm pumps are an ideal option for safely handling wastewater and sludge:

5 Advantages of Using Mudsucker Diaphragm Pumps for Wastewater Treatment

1. Long service life (and low maintenance)

As one of the only diaphragm pump manufacturers that design and build pumps exclusively in North America, Wastecorp offers superior product quality unmatched by competitors. Our Mudsucker line of diaphragm pumps is built with the toughest available materials, such as heat-treated aluminum, reinforced nitrile, and Santoprene, all of which are known for their long flex life and ability to withstand corrosive products. As a result, our pumps typically last for several decades and have low maintenance requirements to function optimally, reducing overall repair time and maintenance costs in the long run. We also offer a full selection of replacement diaphragm pump parts, allowing our clients to further extend the lifespan of our pumps.

2. Ease of use

Mudsucker pumps are easy to set up and simple to maintain, making them suitable for wastewater treatment plants of all sizes. To use a diaphragm pump, ensure the pump is mounted to a rigid baseplate and fitted with an air filter. Then, verify that you’re using the correct suction port and pipe size and regulate the air pressure to two bars on the first startup.

Regular maintenance will help prevent clogging and ensure optimal performance. To service a diaphragm pump, flush the unit with clean water and replace the diaphragms after every 300 hours of use (or at the end of the year, depending on which comes first). Then, inspect the valves and change the oil when needed.

3. Safety

The closed design of diaphragm pumps make it ideal for handling hazardous waste – preventing odors, liquids, and dangerous gasses from escaping during use. Many modern diaphragm pumps also have advanced features, such as chemical leakage detection, stall protection, diaphragm rupture detection, and increased chemical resistance, further enhancing their safety.

Closed operation is critically important during wastewater treatment, due to pumping harmful chemicals and bacteria. Sewage effluent produces toxic gasses, such as hydrogen sulfide and ammonia, which are dangerous if inhaled. To stop these gasses from escaping, Wastecorp’s Mudsucker pumps utilize airtight, durable valves and diaphragms designed to minimize downtime and mitigate operational risks.

4. Versatility

Portable and self-priming, diaphragm pumps can be used virtually anywhere wastewater needs to be treated, and its closed design allows for wet or dry installation. Mudsucker pumps are compatible with a broad range of chemicals, sludges and handle abrasive fluids and high-viscosity slurries with ease. As such, a single diaphragm pump can often be cleaned and reused for different waste management tasks. (Always consult your pump’s manual before processing aggressive solvents to ensure it’s designed for use with hazardous chemicals.)

Diaphragm pumps can be run dry for extended periods, making them suitable for applications with intermittent liquid flow. Their excellent suction and ability to handle suspended solids also make them a perfect fit for challenging vertical applications, such as removing solid waste from septic tanks.

5. Precision

Diaphragm pumps are known for their precise metering and dosing applications. Purifying wastewater for use as drinking water is a complex operation involving multiple steps. Drinking water must be sterilized, de-chlorinated, and controlled for PH, taste, and odor, among other processes.

During the different stages of purification, various chemicals must be dosed in precise quantities to produce the desired final result: safe, clear, and palatable drinking water. Because an electric diaphragm pump can be programmed to deliver specific amounts and combinations of chemicals at set intervals, they make the ideal dosing pump. The sealed, closed design of diaphragm pumps also prevents chemicals and hydraulic fluids from contaminating drinking water during purification.

Shop Our Best Selling Diaphragm Pumps

At Wastecorp, We’re Committed to Clean Water

For over 30 years, Wastecorp has been providing municipalities, private industries, and individuals with reliable pumping solutions to manage wastewater for a cleaner future. Our diverse selection of Mudsucker diaphragm pumps can be customized to fit a wide range of wastewater applications, including use in wastewater treatment plants, septic and sewage treatment plants, and industrial effluent management. We offer multiple customizations, such as pump size and material choices to suit different applications and effluent types, allowing clients to adapt their pump designs to fit their specific needs. You can read here about how Wastecorp provided the Coney Island Wastewater Treatment Plant in New York with new pumps after theirs were damaged from heavy rainfall and flooding.

Contact us today to learn more about how Wastecorp can provide you with pumping solutions to help you manage wastewater safely and effectively. Our experts will be happy to answer your questions, help you find the correct type of pump for your purpose, or customize one of our existing pump designs.