Your Water Trailer Options and Suggestions

Wastecorp is pleased to announce our water trailer pump products. Water trailers, (also referred to as “water buffalo” or "water wagon") provide fresh water distribution

Dry Prime Pumps For Water Authorities

Dry Prime Pumps for Water Authorities and Cities. Water Authorities typically have a need for high flow rate, high suction and discharge pumps for their applications.

Landfill Leachate Pumps

Pumping landfill leachate, wastewater containing solids and other debris is a challenging task that requires high performance pump systems to hold up to day-to-day heavy duty pumping tasks. There are added variables like solids, methane gas and potential site risks that must be taken into account when planning for a landfill wastewater and leachate pumping system.

Advancements in Sewage Pump Technology

Government Water Trailers

Government water trailers are a bit different than industrial water trailers. Government water trailers are typically specified with heavier duty axles and trailers to withstand the punishment of daily use.

How To Operate Your Water Trailer

To learn how to use your Wastecorp water trailer, let’s begin with the basics to get an understanding of how your water trailer operates.

Your water trailer

Silent Pump Options for Municipal Water and Wastewater Treatment Facilities

The New Trash Flow TFVH Series dry prime pump for high head applications.

Wastecorp has launched a high volume and high discharge head pumping solution for municipal

Fabricante Industrial de Bombas

Las Bombas Wastecorp son la nueva generación de equipos de bombeo para gestión de sólidos y lodos industriales, disponibles para procesadores de alimentos, compañías

Agricultural Water Trailers For Farm Use

Water Trailer for farm and other agricultural uses

Whether you own a small farm or are part of a commercial farming organization, the need for mobile water distribution

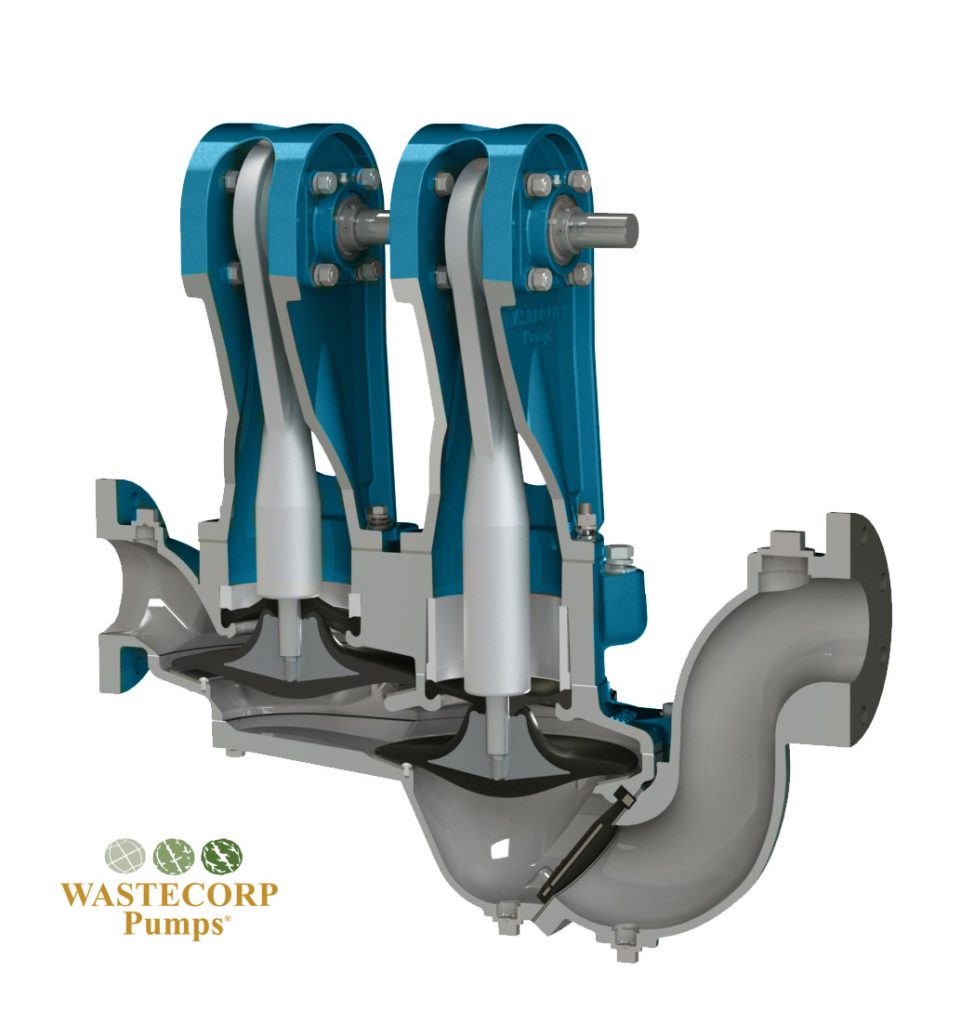

Benefits of Sludge Pro Double Disc Pumps

Sludge Pro Double disc pumps, use a unique induced flow principle to transfer sludges and other fluids. This encompasses a broad spectrum of viscosities, solid contents, and abrasive characteristics. In this article, we delve into specifics of double disc pump design, operational principles, versatile applications, and inherent advantages.