Diaphragm pumps offer powerful, consistent performance, even with variations in liquid viscosity and pressure. However, for smooth operation and long service life, you’ll need to assess your application requirements to ensure the pump you’re using is up to the task. Multiple factors can influence the type of diaphragms, valves, pump casing materials, and power source you need to get the job done, including the liquid you plan to pump and where you’re working. In the following guide, we’ll discuss what you should know before purchasing a diaphragm pump or asking us to build a custom pump tailored to your needs.

5 Things to Consider Before Purchasing a Diaphragm Pump

1. Drive Type

The first thing to consider is the drive mechanism, how you will get the diaphragm to flex and thus the pump to run. The drive type (electric or air-operated, for example) you choose for your diaphragm pump depends on two things: Where you’ll be operating the pump and whether or not you’re working around flammable substances. If you plan to work off-site away from a power source, you’ll need to purchase an air-operated double diaphragm pump (AODD). AODD pumps are also the only safe option for use around flammable liquids or vapours because they don’t present a risk of ignition.

If you’re working near a power source and away from flammable materials, a diaphragm pump with an electric motor may be more suitable for your application. Consider an electric diaphragm pump if your application requires high pressure (AODD pumps can’t exceed the pressure of the forced air supply), or if operating costs are a concern for you. Electric diaphragm pumps use up to 80% less energy than AODD pumps, making them cheaper to run for long periods.

Click here to read more on the different driving mechanisms/types of diaphragm pumps.

2. Valve Type and Size

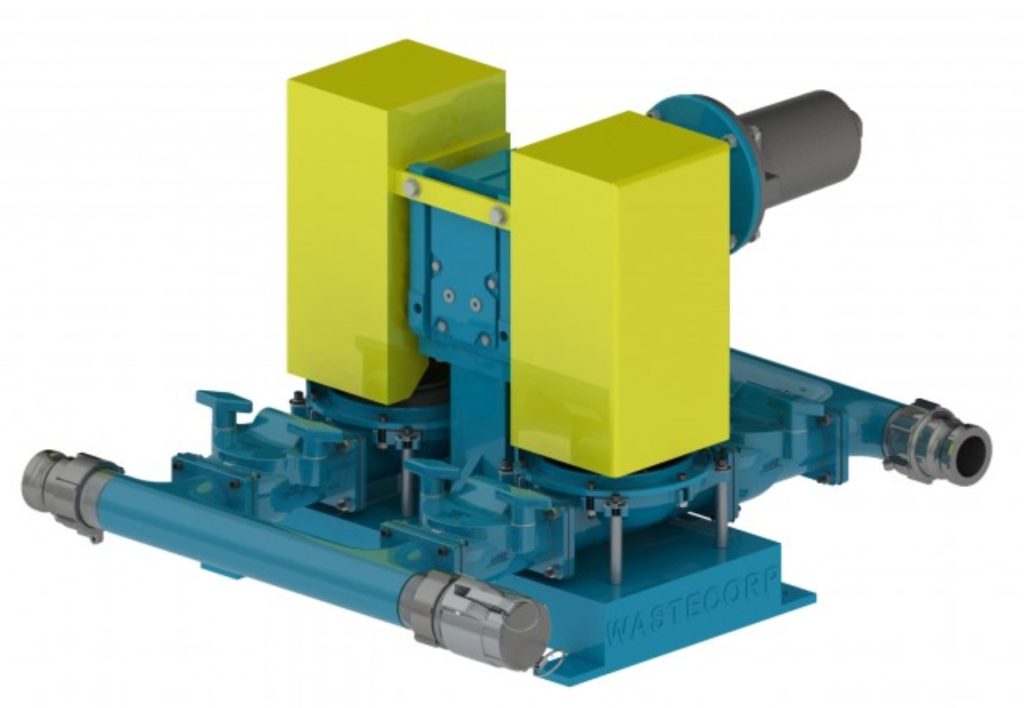

As a general rule, if you want to achieve a high flow rate or pump liquids with large suspended solids, you should choose a pump with a large valve size (3-4 inches) and a robust check valve. Our 4″ Pro Series Hydraulic Diaphragm Pump, for example, combines a heavy ball valve design with a 4″ connection to effectively handle liquids containing solids up to 1¾” in size. Heavy/weighted ball valves are essential when pumping very viscous fluids as they’re capable of cutting through thick materials to seat quickly, preventing backflow.

Another consideration when choosing a valve type is the abrasiveness of the liquid being pumped. For highly abrasive liquids, such as ceramic slip or mineral slurry, choose an abrasion-resistant valve seat (e.g., look for valve seats made of stainless steel rather than rubber).

3. Diaphragms

As the part responsible for propelling liquid and keeping it separate from the pump body, diaphragms are incredibly important to the operation of any diaphragm pump. Failure to properly select and maintain diaphragms can result in liquid leaking into the pump’s casing or motor, causing significant damage and operational safety risks. Before choosing diaphragms for your pump, make sure you understand the qualities of the liquid you intend to pump (e.g., its viscosity, chemical content, abrasiveness or corrosiveness, maximum solids size, etc.) Then, review the following criteria to find the best diaphragms for your application:

Chemical & Abrasion Resistance

Before selecting a set of diaphragms, you should always refer to a detailed chemical resistance guide. Diaphragm materials vary widely in the type of chemicals they can withstand: just because a material offers good overall chemical resistance, that doesn’t guarantee it will be compatible with the specific chemical you’re handling. There are, however, some general material guidelines you can refer to when assessing chemical and abrasion resistance:

Santoprene (TPO)

Santoprene is a highly durable thermoplastic rubber designed for superior chemical and abrasion resistance. Santoprene is used in many of our Wastecorp diaphragm pumps due to its extremely long flex life and versatility; Santoprene can handle most alcohols, ketones, glycols, esters, acids, salts and bases without degrading. However, it should not be used with certain volatile chemical compounds, such as benzene/chlorobenzene, chloroform, cyclohexane, kerosene, trichloroethylene, naphtha, toluene, or xylene. For this reason, Santoprene is unsuitable for pumping gasoline and other fuels.

Neoprene

A rubber compound, neoprene offers mild to moderate chemical resistance, good abrasion resistance, and long flex life. It can safely withstand some oils, but not esters, ketones, acetone, or strong acids, and some hydrocarbons can damage Neoprene over time. Neoprene may also absorb water.

Nitrile (Buna N)

Nitrile offers moderate abrasion resistance and excellent resistance to a variety of hydrocarbons, including oil, petroleum-based fuels, grease, lubricants, hydraulic fluid, motor oil, turpentine, and other compounds often used in painting and automotive applications. However, Buna N has a reduced flex life compared to neoprene and Santoprene.

Like neoprene, nitrile is not suitable for use with harsh chemicals, ketones, acetone, or strong acids.

FKM (Viton)

FKM can resist very high temperatures and offers broad chemical compatibility, being able to withstand multiple solvents, ozone, mineral oil, fuels, hydraulic fluids, most acids, and chlorinated hydrocarbons. However, it isn’t recommended for use with ketones, amines, certain esters and ethers, nitro hydrocarbons, and very potent acids.

EPDM

EPDM is the diaphragm material of choice for use with many corrosive fluids such as solvents, brake fluids, and hydraulic fluids. It also offers enhanced temperature resistance, with a wide range of operating temperatures. However, it should not be used with oils, fats, grease, petroleum-based fluids, or highly concentrated acids.

TPEE (Hytrel)

TPEE is among the toughest diaphragm materials, offering excellent resistance to temperature extremes, impact, and flex fatigue. It’s a common choice for use with very abrasive liquids and many industrial chemicals, oils and solvents.

PTFE (Teflon)

PTFE offers the highest level of chemical resistance, being suitable for use with most aromatic and chlorinated hydrocarbons, acids, caustics, ketones and acetates.

Temperature Limits

Before selecting a diaphragm material, consider the temperatures of the environment where your pump will be operating and the fluid it will be pumping. The temperature ranges of various diaphragm materials are outlined below:

Neoprene: -18°C to 82°C

Buna N: -12°C to 82°C

FKM: -29°C to 120°C

EPD: -50°C to 100°C

Santoprene: -23°C to 120°C

TPEE: -18°C to 120°C

PTFE: 4°C to 100°C

Suction Capability

How much “suction lift” your application requires is another important factor to consider when choosing diaphragms. Some materials, like Teflon, are very rigid and may therefore become damaged by high vacuum pressure, while rubber compounds readily bounce back. If you need both suction lift and superior chemical resistance, you may need to purchase two-piece bonded diaphragms, which combine the durability of one material (such as Teflon or stainless steel) with the flexibility of rubber.

Hygiene Standards

If you plan to use your pump for applications related to food, beverage, pharmaceutical, or cosmetics manufacturing, you’ll need to use diaphragms that comply with hygienic standards. Two-piece bonded PTFE diaphragms are often used for applications requiring enhanced hygiene.

4. Pump Body Material

Common diaphragm pump materials include cast iron, steel, aluminum alloy, and certain highly specialized hard plastics, such as fluorine plastic (PVDF). If you plan to pump non-corrosive liquids, choose a pump with a metal body (e.g., cast iron or aluminum alloy) as metal pumps offer excellent durability when not exposed to corrosive substances. Pumps with a metal body are also less prone to leakage than plastic pumps and can withstand high levels of abrasion from suspended solids.

For corrosive liquids, on the other hand, plastic and PVDF pumps are usually recommended as they will not rust or otherwise degrade, giving your pump a longer service life. Most plastic pumps can safely transfer acids, caustics, and bleach; however, you should always consult your pump’s manual to verify that it’s suitable for your application before pumping a corrosive liquid. To prevent leakage, inspect plastic pumps regularly for loose fasteners and tighten them as needed.

Operating temperature also plays a role in material selection: If you plan to pump liquids at very hot temperatures, you will need to use a stainless steel or PVDF pump, as both materials offer excellent thermal resistance. If pumping an abrasive liquid at high temperatures, choose a stainless steel pump; for highly corrosive liquids, PVDF may be a better choice in certain situations.

5. Flow Rate

The final step before buying a diaphragm pump is to calculate the flow rate needed for your application. Diaphragm pumps can transfer liquid at rates as low as one gallon per minute up to hundreds of gallons per minute, depending on the pump’s size and operational speeds. To reduce wear on your pump, we strongly recommend selecting a pump that has twice the flow rate you require. Running a pump at 50% of its maximum capacity during typical operation will greatly extend its service life.

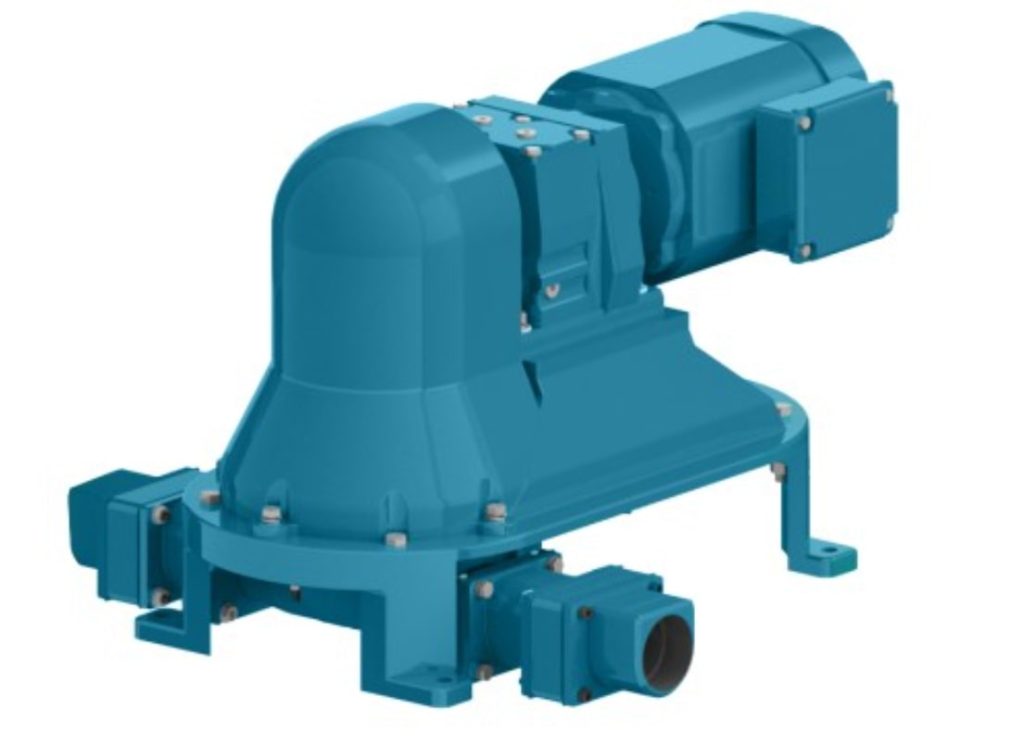

Ask the Experts at Wastecorp For Advice on Choosing a Diaphragm Pump

Choosing the correct diaphragm pump will protect your pump from premature damage and ensure safe usage. If you would like to review your options or have a diaphragm pump designed to fit your specific application, Wastecorp can help. As a pump manufacturer, we offer custom diaphragm pumps and a wide range of diaphragm pump parts and accessories, giving our pumps unmatched versatility. Plus, all of our pumps are designed and manufactured in North America, guaranteeing superior product quality and reliability. Contact us today to get started or browse our extensive selection of diaphragm pumps: