Sludge Pro Double Disc Pumps, use a unique induced flow principle to transfer sludges and other fluids. This encompasses a broad spectrum of viscosities, solid contents, and abrasive characteristics. In this article, we delve into specifics of double disc pump design, operational principles, versatile applications, and inherent advantages.

Double Disc Pump Design and Operational Principles:

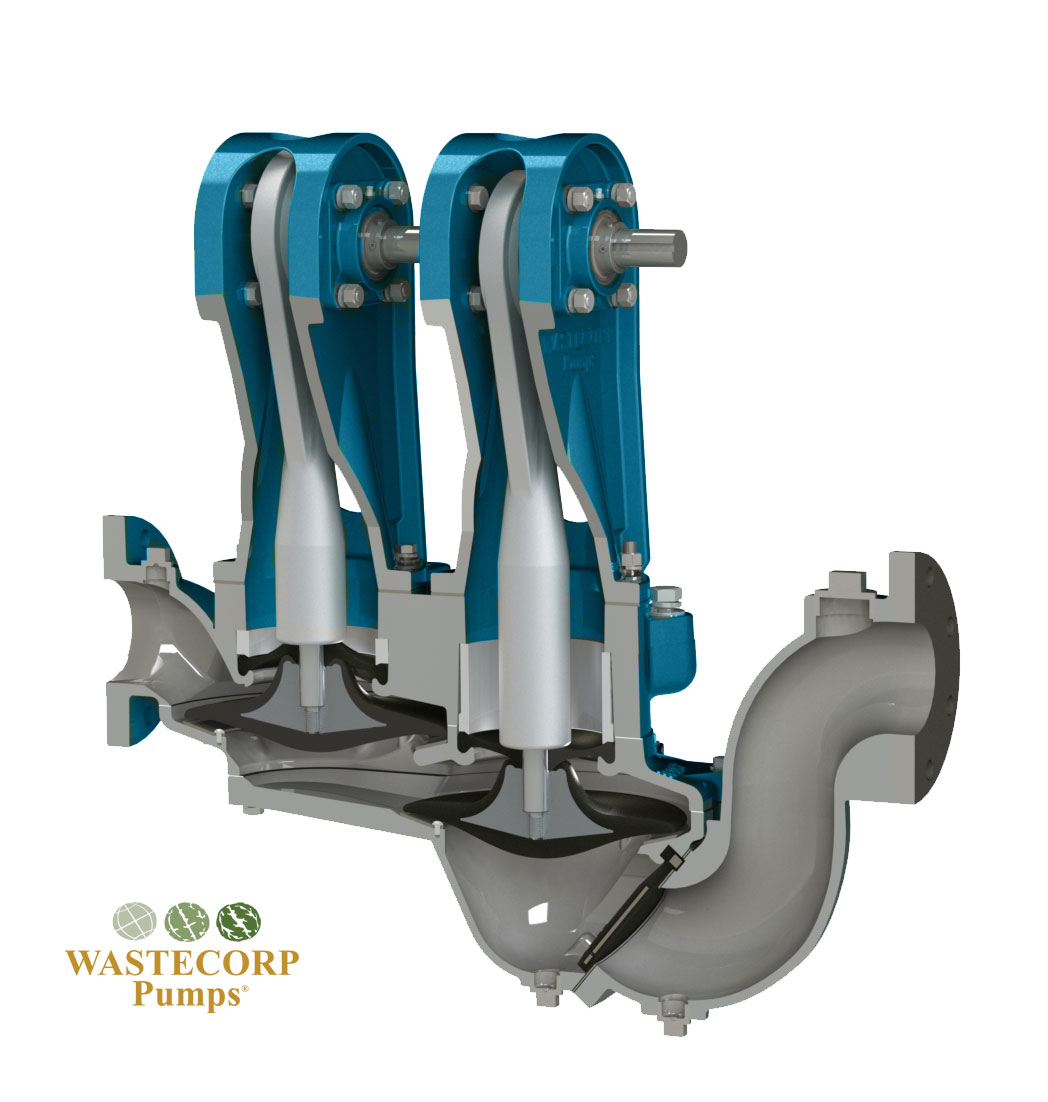

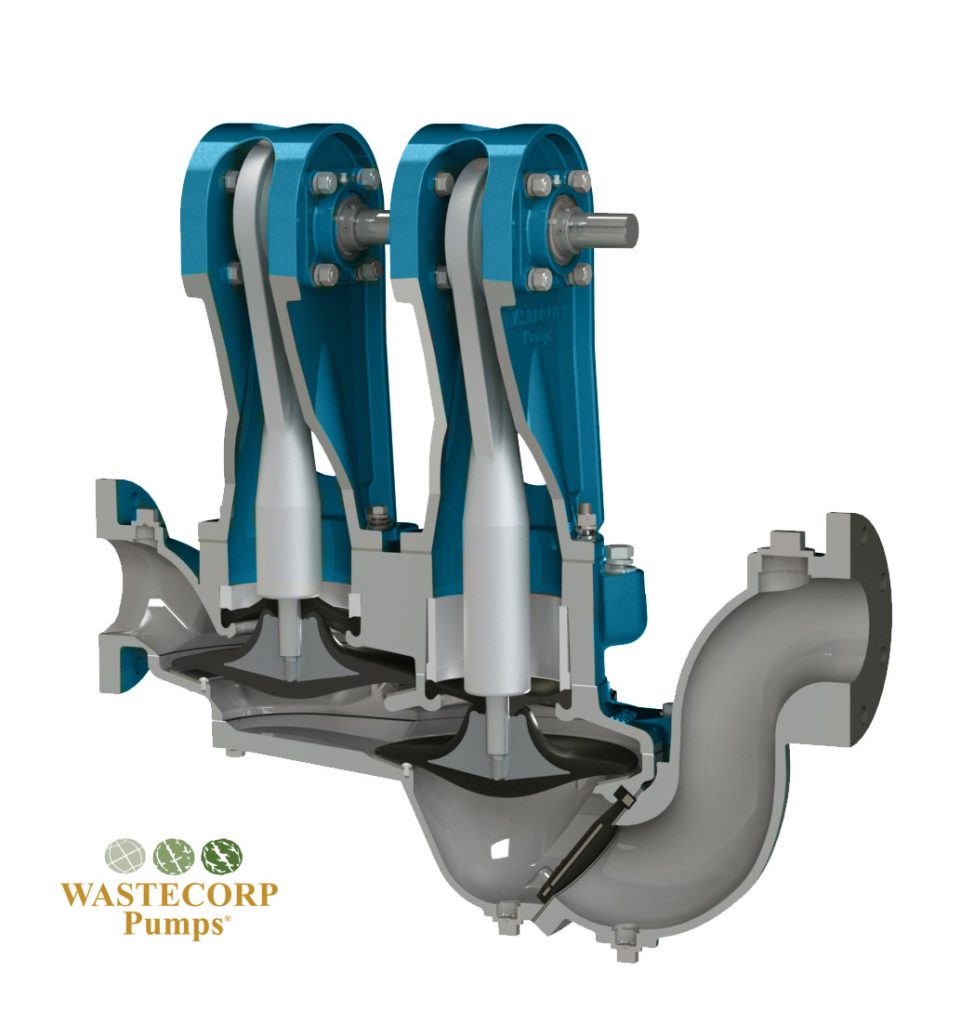

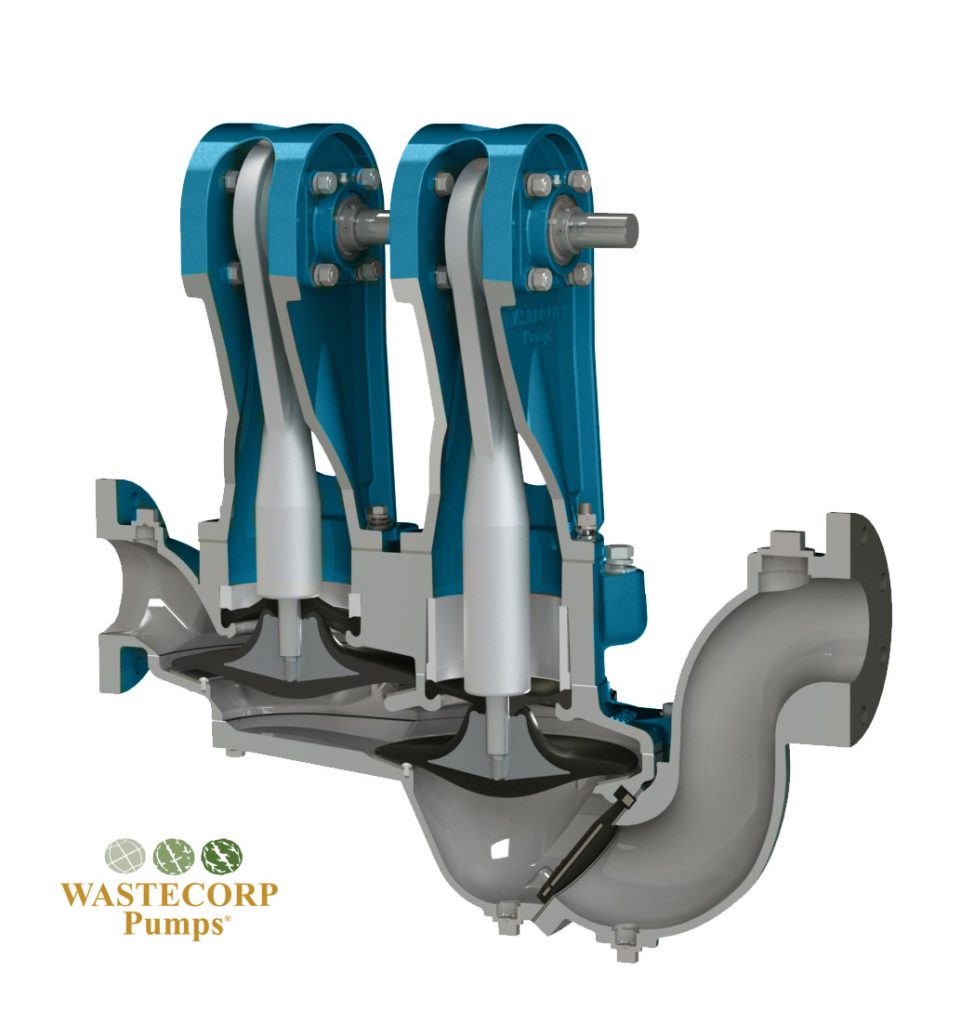

Pump Construction: At the heart of double disc pumps lies a robust housing enclosing two free floating discs that work in unison. While the first disc is drawing the fluid in, the second disc (upstream) is aiding in discharging the fluid.

Fluid Conveyance: The reciprocating motion of the discs ensures a continuous and uniform flow of fluids through the pump. This minimizes turbulence and ensuring optimal fluid conveyance.

Low Shear: A distinguishing feature of the Sludge Pro double disc pump is their ability to minimize shear forces exerted on conveyed fluids. This characteristic is essential for handling delicate fluids without compromising their integrity or consistency.

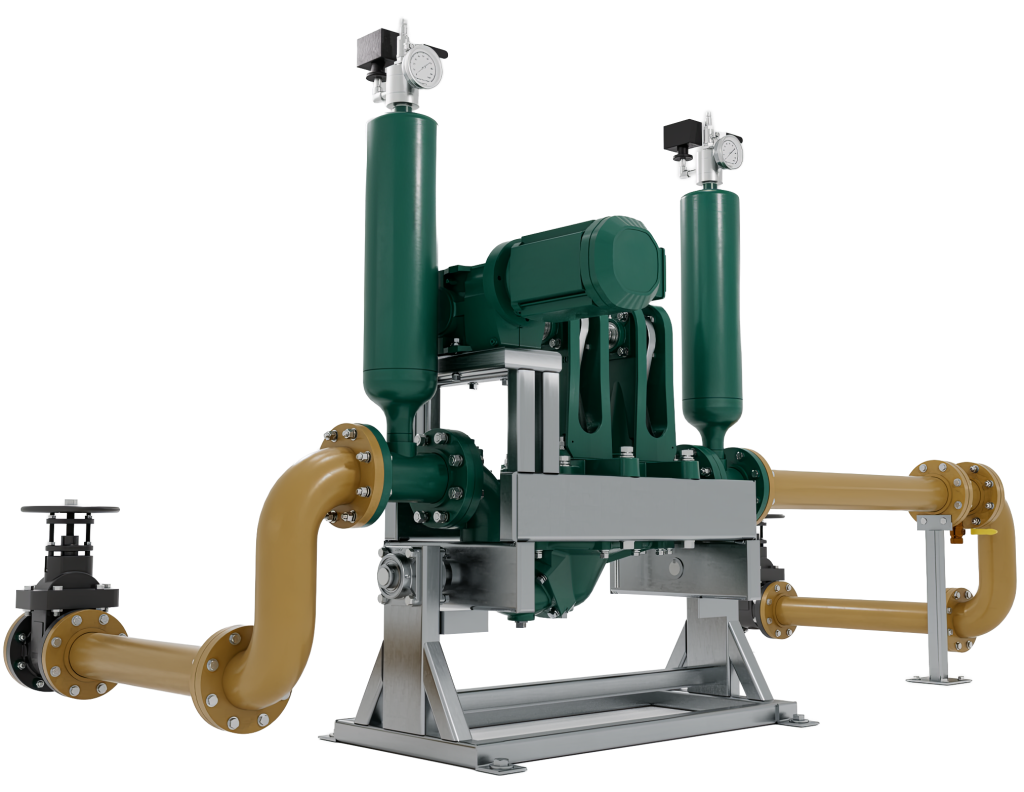

Material Selection: Double disc pumps are meticulously constructed from high-quality materials. Sludge Pro materials of construction are chosen for their durability, corrosion resistance, and ability to withstand the rigors of fluid handling operations.

Double Disc Potential Uses

Sludge Pro Double disc pumps find widespread utilization across an array of industries, where the efficient conveyance of fluids is paramount:

● Primary sludge pump

● Thickened sludge transfer

● Scum transfer

● Belt filter press feed

● Industrial slurry and sludge transfer

● Centrifuge feed

● Rotary press feed

● Screw press feed pump

● Waste activated sludge

● Food process slurry

Double Disc Pump Applications

Muncipal Sewage Pumps: Sludge Pro double disc pumps are the idea primary sewage pump, scum pumps, lime slurry pumps, belt filter press feed equipment, screw press pump and much more.

Mining and Minerals: Within the mining sector, these pumps are indispensable for handling abrasive slurries, transferring tailings, and facilitating mineral processing operations.

Food and Beverage: In the food and beverage industry, double disc pumps are instrumental in pumping viscous food products, including sauces, syrups, and dairy products, while maintaining product integrity and consistency.

Chemical Processing: Double disc pumps are widely employed in chemical processing facilities for the transfer of corrosive fluids, solvents, and specialty chemicals, ensuring safe and efficient production processes.

Oil and Gas: Within the oil and gas industry, these pumps are deployed for crude oil transfer, handling drilling mud, and facilitating various upstream and downstream processes essential for hydrocarbon extraction and processing operations.

Benefits of Using Double Disc Pumps

Versatility: These pumps are capable of efficiently handling a diverse range of fluids, including viscous liquids, solids, and abrasive materials, making them highly versatile across various industries and applications.

Low Maintenance: With minimal moving parts and robust construction, double disc pumps require minimal maintenance, reducing downtime and operational costs.

Gentle Handling: The low shear forces exerted by double disc pumps ensure gentle handling of delicate fluids, preserving their integrity and properties throughout the pumping process.

Efficiency: Double disc pumps deliver consistent and reliable performance, even when handling challenging fluids, ensuring optimal operational efficiency and productivity.

Non-Clogging: These pumps exhibit exceptional resistance to clogging, making them suitable for fluids with high solid content and minimizing the risk of downtime and maintenance interventions.

Self-Priming: Certain variants of double disc pumps feature self-priming capabilities, simplifying installation and operation and enhancing overall operational efficiency.

Longevity: Constructed from durable materials and engineered for reliability, double disc pumps offer a long service life, ensuring enduring performance and value over time.

Summary

Double disc pumps represent a dependable solution for fluid transportation across a myriad of industrial applications. Their versatility, efficiency, and reliability make them indispensable components in fluid handling systems, contributing to enhanced productivity, operational efficiency, and cost-effectiveness across various industries and sectors. For more information from a double disc pump manufacturer contact 1-888-829-2782 or email info@wastecorp.com