How to Pump Out and Have Potable Water With One Pump System

Hi, the DPW for LA City is looking for a more productive way to pump out septic waste and dirty standing water and then rinse the area after use. We would preferably want one pump and tank system to do the job.

Food Processing Pump: Video Case Study

If your facility is considering a food processing pump technology then check out this video case study here. The video shows a Mud Sucker Diaphragm pump at a poultry processing plant transferring up to 110 GPM. You may not want to view until after lunch because it shows the tough chicken waste that the Mud Sucker B Series can transfer like blood, beaks, fat and feet.

New 1025 Gallon Skidded Water Wagon

Wastecorp is pleased to launch our new exclusively designed skidded water wagon with lifting bail. The 1025 skid mounted water wagon shown here is part of Wastecorp’s growing family of water trailer products for dust control, construction sites and fresh water delivery for any purpose. The skid mounted water distribution system was recently commissioned as a fleet solution for a Toronto based construction company.

The lifting bail and forged steel design allows the water wagon to be attached to a crane and hoisted to skyscrapers and other hard to reach areas on construction sites. Tanks are available from 500-2500 gallon sizes in this configuration and feature several models of trash pumps for high pressure water deliv

New 4” Diaphragm Pumps Now Available

If you’re looking for a flapper valve style diaphragm pump with a 4” connection and more pumping power, consider Wastecorp’s new Mud Sucker 4FA Series diaphragm pumps available with electric, engine, AOD or hydraulic drive systems.

Pump Out for Water Tour Boats and Cruise Vessels

Pumping Out Bilge Waste

Like all commercial vessels, tour boat operators are required to properly dispose of holding tank (bilge) waste. There are many methods of doing so ranging from a fixed pump out station, using a pump out vessel, a third party service or having your own pumps to do the job.

We’re profiling the case of one New York City based tour boat operator who uses the Mud Sucker 2FA-EC diaphragm pump to manage their pump out operations. First, some background. New York’s five boroughs are home to over a dozen ferry operators, water tours, water taxis – both public and private. Millions of visitors and residents use any one of these services every year. Managing the kind of waste associated with so much visitor traffic requires some creativity and a pump out that can do the job without hassles over the long haul. Keeping the harbors clean is a mission backed by most New Yorker’s and the Mayor’s office.

Many operators use the Mud Sucker as a quick way to empty both waste oil (from their kitchens) and their vessels’ waste holding tanks with fluid transfer capabilities ranging from 20-160 GPM. The added advantage with the Mud Sucker is that it can transfer waste oil including waste trap grease and used vegetable oil. Since many boat operators have a kitchen for entertaining passengers as well as restrooms, it only makes sense to have a pump that can transfer both bilge waste and cooking oil.

In the case of one of our recent customers in Manhattan’s Chelsea neighbourhood, the end user have multiple tour boats docked within a short distance of each other. At the height of tourist season (April-September), these boats are coming in and out of the pier from sun up to sun down. The Mud Sucker 2FA-EC with a wheel kit (shown here) easily transfers the waste holding tank waste into an environmentally fri

Diaphragm Pump Design and Engineering

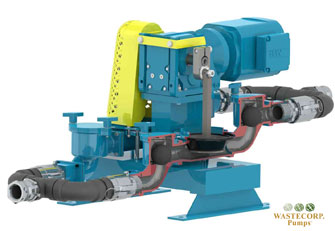

Wastecorp didn’t invent the diaphragm pump but when we introduced the Mud Sucker diaphragm pump product line almost 25 years ago we set out to innovate and radically transform how customers transfer fluids. One of our first Mud Sucker models, the 4BW-MDD Series is a walking beam style pump that uses a heavy duty piston motion to move heavier slurries found in coal mine, pulp and paper and municipal sewage applications. What makes this pump so special is its ability to transfer heavy solids with a choice of Siemens gear box and motor, gas or diesel engine (Yanmar diesel model shown).

Driving the Conversation in The Diaphragm Pump Business

The variety of pumping applications we see from the field grows everyday; From biodiesel production, bauxite, sugar refining to refineries and waste water treatment. And, each of these applications gets improved pumping performance with different components designed for specific applications. With Wastecorp’s flex-production floor, pump models like the 4BW-MDD can get stainless steel valve seats for customers who move corrosive fluids or FDA compliant internal coatings for customers in the food processing industry.

Wastecorp’s improved production efficiency gets translated into cost savings for the pump user in a variety of ways.

First, you get the pump you need without having to overkill your pump purchase with the tradi

Tote Tanks Now Available With Mud Sucker Pump Out Systems

Tote tanks are an effective temporary wastewater collection and containment system designed for a variety of industries including RV/Septic, waste oil, general wastewater, industrial chemical and much more. Wastecorp’s Mud Sucker diaphragm pumps are now available with a tote package, available in a variety of tank sizes including polyethylene and stainless steel. The tote system you see here includes a lifting pallet, designed to easily maneuver and move the tote around your job site to collect what ever you are pumping. The Mud Sucker diaphragm pump you see top left features a heavy duty DC motor which can be connected to a generator or vehicle power source.

There are several specialized tote tank pump out systems (second photo) that can be mounted inside service vehicles that collect restaurant waste trap grease, used oil from bus depots and auto service companies.

Wastecorp tote tank pump out systems are designed specially for your application. read more

Wastecorp Keeps Pumping Through New England Storm

The show was to kick off Wastecorp’s 2015 promotional campaign with its Sludge Pro Double Disc Pumps, Mud Sucker Diaphragm Pumps, Trash Flow Trash Pumps and Sludge Master Plunger Pumps. The NEWEA annual conference in January involves many of Wastecorp’s nearby Wastewater Treatment Facilities in Plymouth, Providence, City of Boston, Sandwich, City of New Haven

Pumps in Upstate New York

It’s not often that we get to exhibit our wastewater pumps and systems so close to home. But during the week of April 14th Wastecorp will be exhibiting our new disc pumps, Mud Sucker Diaphragm pumps and Trash Flow Trash Pumps at the New York Rural Water Association annual technical conference at Turning Stone Casino in Verona, New York.

Pumping Out of Totes

You see them everywhere: tote tanks with steel or aluminum cages that temporarily store a variety of liquids including waste oil, septic waste, restaurant grease trap waste and industrial fluids. What many people don’t know is that having a proper diaphragm pump to transfer liquid both into or out of the tank can make all the difference in having safe and clean pumps out versus pump outs that leave the possibility that potentially hazardous liquids may contaminate your job site or drink water.