Industrial Water and Waste Oil Pumping for Railroads

One of the questions we get most often from railroads is how to cost effectively install a new pump system that can pump liquids as varied as oil or chemicals from rail car tankers to septic waste from locomotive restrooms. Manny R from Norfolk Virginia exemplifies the pumps for railroad.

Pumping Out Tanks With Diaphragm Pumps

You name the tank that needs to be pumped out and we have heard of at least a few customer applications that correspond with that tank. Underground septic tanks, lagoon transfer, transport truck tankers, locomotive tankers, waste pits and waste vegetable oil drums are among the most popular.

Commercial Waste Trap Grease Pumps – What to Know

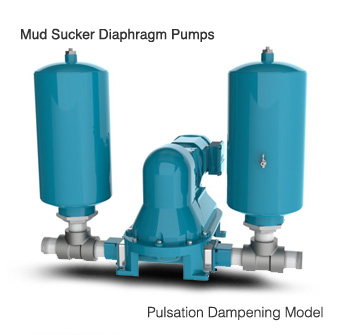

Waste trap grease pumps for commercial applications can be used for a wide variety of applications involving pumping grease from the source to a suitable treatment area. One such pump for pumping waste trap grease is the Mud Sucker Diaphragm pump which is used in shopping centers, hospitals, school cafeterias, restaurants, prisons and other government institutions where pumping grease for treatment is required.

Diaphragm Pump for Sewage Pumping

If your pump project calls for primary sludge pumps under 220 GPM, the Mud Sucker Double Diaphragm pump is something you should consider for municipal sewage and industrial sludge pumping applications.

Case in point: A Northeast urban wastewater treatment plant upgrade and expansion recently

specified and installed two Mud Sucker 3B-EC-DD Series double diaphragm pumps with one and three quarter inch solids handling capabilities These Mud Sucker’s pump primary slud

Pumps: How to Maintain a Continuous Flow and Minimize Pulsation

With pumping applications, one of the challenges you face especially when pumping thinner liquids, is to maintain continuous flow without “jerking the hose” or disruptions in pump productivity. One of the consulting engineering firms we have worked with in California illustrates this point well:

Diaphragm Pump Technology Advances

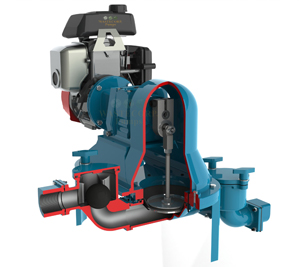

At the heart of the latest diaphragm pump technology update is “quick release yoke technology” The principle here is to make it easier for the operator of the pump to conduct routine maintenance. Quick release technology has been available up until this point on the Mud Sucker premium B Series professional line. This type of diaphragm pump uses ball valves or check ball technology to move wastewater. However, in 2020, the Mud Sucker FA Series diaphragm pump is also available with quick release technology.

The diaphragm flapper material is a severe duty rated elastomer for waste oil pumping and general wastewater pumping applications. You can also pump select corrosive fluids with this diaphragm pump but should check with the factory with your application first.

In the photo above, you see the new diaphragm pump, Mud Sucker model read more

Diaphragm Pump Design and Engineering

Wastecorp didn’t invent the diaphragm pump but when we introduced the Mud Sucker diaphragm pump product line almost 25 years ago we set out to innovate and radically transform how customers transfer fluids. One of our first Mud Sucker models, the 4BW-MDD Series is a walking beam style pump that uses a heavy duty piston motion to move heavier slurries found in coal mine, pulp and paper and municipal sewage applications. What makes this pump so special is its ability to transfer heavy solids with a choice of Siemens gear box and motor, gas or diesel engine (Yanmar diesel model shown).

Driving the Conversation in The Diaphragm Pump Business

The variety of pumping applications we see from the field grows everyday; From biodiesel production, bauxite, sugar refining to refineries and waste water treatment. And, each of these applications gets improved pumping performance with different components designed for specific applications. With Wastecorp’s flex-production floor, pump models like the 4BW-MDD can get stainless steel valve seats for customers who move corrosive fluids or FDA compliant internal coatings for customers in the food processing industry.

Wastecorp’s improved production efficiency gets translated into cost savings for the pump user in a variety of ways.

First, you get the pump you need without having to overkill your pump purchase with the traditional cook