Sludge Handling Equipment Improvement Project – Municipal

When Wastecorp works with consulting engineers and operators on sewage treatment plant improvements, we look to limiting the footprint inside the plant due to the

Sap Pumping Equipment : Maple Syrup and Production Pumps

We are quickly approaching the season where maple-sugaring equipment comes into high demand in Northern areas of the United States and Canada. As a pump manufacturer, Wastecorp sees two very common client needs: The first is to design and manufacture pumps for maple syrup farms with between 400 and 600 taps. The second...

How to Plan a Marine Pump Out Station

What Does A Marine Pump Out Station Do?

A marine pump out station is a facility that allows for boat owners to pump out sewage from their boat’s holding tanks. Having a pump out station for boats is essential for maintaining clean waterways and preventing pollution.

Importance of Planning Your Marine Pump Out Station

Planning a marine pump out station ensures optimal functionality and waste management at your marina. The process involves knowing your marina’s available space, daily traffic and average vessel size to ensure you are getting the appropriate equipment. Consulting other marinas and marine pump experts ahead of when you actually need it installed can also provide valuable insights.

Wastecorp, a leading marine pump out manufacturer, has over the past few years observed an emerging trend: marinas experiencing increased boat and yacht traffic. In fact, it’s forecasted that the recreational boat market will reach USD 27.45 billion by 2030. As such, it’s crucial that your current marine pump out plan can also accommodate future growth effectively.

Compare Double Disc Pumps With Single Disc Pumps

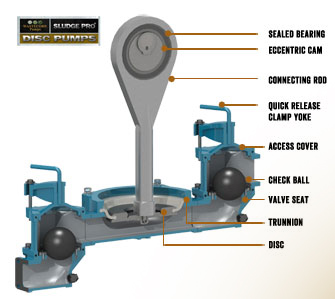

Since we launched the Sludge Pro Disc Pump product line, there have been several questions as to whether or not a single disc or double disc pump is more appropriate for a specific wastewater treatment application.

To be clear, there is not always a need for a double disc pump, a single disc pump will fit the pump specification properly. One of the reasons why consulting engineers and contractors have put the double disc pump specification in place is because there has been few other alternatives.

Commercial Waste Trap Grease Pumps – What to know

Mud Sucker brand grease trap pump shown at new Miami upscale shopping center. Pumps restaurant grease trap waste

Waste trap grease pumps for commercial applications

Double Disc Pump Comparison Guide for Engineers, Operators and Pump Distributors

Wastecorp has published a double disc pump comparison guide for consulting engineers, end users and pump distributors. This resource explains the difference between two different pump types and the methods each use to pump sewage, sludge and wastewater. You can download this comparison guide by clicking here or continuing to read below.

Who is Wastecorp?

Wastecorp Pumps is an ISO 9001 and ISO 14001 certified pump manufacturer. Wastecorp manufactures the Sludge Pro brand double disc pump. The company specializes in sewage pump and wastewater pump manufacturing. This includes multiple products for municipal/industrial applications. Wastecorp has manufactured pumps since 1993 in the United States and Canada. Information about Sludge Pro Double Disc Pumps can be found at

https://wastecorp.com/Products/Disc-Pumps

What is a Penn Valley Pump (PVP)?

The Penn Valley pump is a diaphragm pump. PVP has fully acknowledged this in their patent # US 7,559,753 B2. The patent references George Burrage’s (a family member of PVP President) patent application # GB 2013287A as the basis of construction for the PVP pump. Nowhere in GB 2013287A does it reference a disc at all. This legal document fully acknowledges the fact that the Penn Valley pump is a diaphragm pump. PVP also references the use of diaphragms in all of their trademark registrations.

What is The Difference Between Penn Valley (PVP) and Sludge Pro Pumps?

Sludge Pro double disc pumps are available with either a clack valve or a ball valve configuration. The operator selects one or the other. As of 2017, Penn Val

Grout Pumps for Commercial and Residential Applications

As the weather improves for commercial grouting jobs it gives us an opportunity to address contractor concerns. One of the comments we heard from contractors who work with grouting jobs before the Sludge Sucker grout pump was made available, is that there was a lack of dependable, compact grout pumps that could easily be moved to job sites with tight spaces. Wastecorp went to work and designed/engineered the Sludge Sucker Professional Grout Pump. Now, this has not been featured on Shark Tank (yet) but we have been thinking about it due to its positive response from construction professionals. Since then, the Sludge Sucker has become a staple for commercial contractors and public works crews to grout door frames, pilings, slab jacking, void filling, mud jacking and many other commercial grouting applications.

New Grout Pump Crank Arm

Our 2nd generation Sludge Sucker has just been launched with exciting new components to enable long life cycle use.

The first major change is with the crank arm mechanism. The new grout pump crank arm has been designe

How to Pump Out and Have Potable Water With One Pump System

Hi, the DPW for LA City is looking for a more productive way to pump out septic waste and dirty standing water and then rinse the area after use. We would preferably want one pump and tank system to do the job.

Wastecorp Keeps Pumping Through New England Storm

The show was to kick off Wastecorp’s 2015 promotional campaign with its Sludge Pro Double Disc Pumps, Mud Sucker Diaphragm Pumps, Trash Flow Trash Pumps and Sludge Master Plunger Pumps. The NEWEA annual conference in January involves many of Wastecorp’s nearby Wastewater Treatment Facilities in Plymouth, Providence, City of Boston, Sandwich, City of New Haven