Connecticut Pump Options

Wastecorp has proudly served Connecticut's municipal and industrial pumping needs over over 20 years. From Darien, Derby, Hartford, Mystric and beyond our plunger pumps, diaphragm pumps trash pumps and now disc pumps work hard for the millions who indirectly depend on reliable pumping equipment to keep sewage in its place and water flowing.

Food Waste Pumps – Food Processing Facilities

The challenge for food waste processors is finding pumps for their applications that are versatile and robust enough to pump through a variety of conditions. This was just the case for a Fresno, California based

alternative energy company who earned a multi-year contract to accept expired and spoiled canned tomato paste, tomato sauce, fruit juice, ketchup and bulk tomatoes for Fresno and Bakersfield area grocery stores, prisons, hospitals, food preparation companies and more.

Wastecorp was contacted by a South New Jersey WWTP to provide upgraded sewage pumps to transfer wastewater,

Diaphragm Pumps Now Available With Control Panels

One of the trending customer requests this past year is custom diaphragm pump stations equipped with control panels and mobility options. To give you an example (and some ideas for your own pump application), one of our customers who happens to be one of the largest snack food producers globally, contacted Wastecorp’s engineering department asking for design proposals for a 3″ diaphragm pump out system complete with a mobility kit and the ability to directly control the pump operation. The diaphragm pump unit needed to be manufactured to maneuver easily on the factory floor aisles with custom dimensions. The pumps travel throughout the facility transferring chocolate based waste slurry and vegetable oil residues.

Look to the left and this is what our pump engineers came up with. This is the 3FA-EC diaphragm pump control panel model with e-stop, push bottom start and a specialized float system which detects when the pump should begin operating and automatically turn off. The customer ended up ordering 10 units for other facilities. The best part of this case study is that Wastecorp and our customer are in constant contact reviewing the benefits of the pump system and making design changes for future facility needs. We work one-on-one for custom results and constant improvement.

The Mud Sucker diaphragm pump with transformer you see here is designed with a more compact installation in mind. The customer ordered this Mud Sucker 3″ diaphragm pump for assembly line food processing waste transfer tasks. This unit transfers waste pit slurries and detects when the pit is empty or in need of pumping. The pump is

Compact Marine Pump Out System Makes Debut

If your marina is looking for a compact dock side pump out station this season check out the ultra compact Mud Sucker Marine pump out system. The best part about this system is that it was completely engineered with marina operator input. Last season, we asked marinas what new pump out products would most benefit their boaters and improve the overall sanitation system of their marina.

Almost unanimously, marinas expected more compact systems for 2020, with easy-to-use controls and safety built in. Our Mud Sucker pump outs were once again given top ratings by both boaters and marine operators.

What makes the Mud Sucker Compact marine pump out unique is that the entire pump out system sits on a pedestal starting at less than 34″ (49″ with hose stand included) W x 43″ H. You choose between a fiberglass or stainless steel enclosure. All the accessories you need, like a spill proof universal pump out nozzle for any vessel, crush proof hosing, hose stand and standard on/off function is included. Like all of our pump out systems, you can lock the enclosure for added security.

New for this season, you can customize your pump out with automated remote controls and stainless steel hardware for the ultimate in convenience and corrosion resistance. For U.S. customers, make sure you apply for a grant under the read more

How to Select a Pump for Paint Manufacturing

-

When paint production facilities require pumping equipment to transfer paint there are a number of factors that should be considered. From understanding the abrasives in the paint to the configuration of your production floor here are some tips to keep in mind:

1. What is the consistency of the paint being pumped?

This is one of the most important considerations when selecting the right pumping equipment.

Many customers have experimented with several different pump options to no avail. Most paint transfer application involve moving a thicker slurry. In the first photo you see here, we recommended that the customer go with a Mud Sucker ball valve style diaph

Finding Diaphragm Pump Parts for Any Make

Older diaphragm pump parts can be difficult to find and repair kits or overhauls even trickier. However, a few steps can help you identify the components you need to get your pump up and running again. Replacement diaphragms are the easiest to match. We come across Mud Sucker, Home Lite, Mud Hog, AMT, Tsurumi, Multiquip, Wacker and Honda diaphragm pumps all the time that we can match. Repair kits like pump rods, covers, flapper valves and gaskets might be a bit tougher.

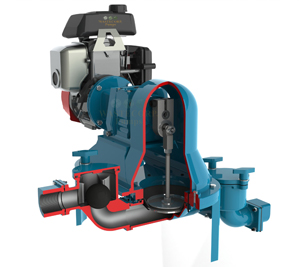

Trash Pump Updates – The New Trash Flow

Looking for a trash pump? Wastecorp is pleased to launch new options for you with the new Trash Flow Trash pump line. Trash Flow pumps are available as self priming centrifugal models for municipal and industrial applications as well as compact trash pumps for contractor use. What makes this product line our best ever is that the Trash Flow is interchangeable with many existing makes on the market today like Gorman Rupp T Series and Super T Series.

The Trash Flow pump product line is available in 2”-12” pump models with fluid handling capabilities up to 6500 US GPM. Choose from a variety of impeller options including multi vane and double vane for solids handling. With our self priming Executioner solids management system, you can eradicate tough solids that may cause clogs. Trash Flow’s are available with stainless steel internals, an adjustable wear plate carrier, back pull out design and optional John Crane mechanical seals for long life cycles and minimal maintenance.

We’ve added more options to our engine driven TFCC-M Series too. You choose from skid mounted, trailer mounted or our Husher silent pump series with an enclosure that substantially reduces noise. read more

Diaphragm Pump Technology Advances

Diaphragm pump technology for wastewater pumping, waste oil, septic and food processing applications has advanced. Wastecorp, a designer and manufacturer of diaphragm pumps, has invested in R&D to build better diaphragm pumps. Wastecorp’s vision is to become the worldwide leader in diaphragm pump technology and reaching this goal is becoming closer for the company every year.

At the heart of the latest diaphragm pump technology update is “quick release yoke technology” The principle here is to make it easier for the operator of the pump to conduct routine maintenance. Quick release technology has been available up until this point on the Mud Sucker premium B Series professional line. This type of diaphragm pump uses ball valves or check ball technology to move wastewater. However, in 2020, the Mud Sucker FA Series diaphragm pump is also available with quick release technology.

The diaphragm flapper material is a severe duty rated elastomer for waste oil pumping and general wastewater pumping applications. You can also pump select corrosive fluids with this diaphragm pump but should check with the factory with your application first.

In the photo above, you see the new diaphragm pump, Mud Sucker model read more

Water Hauling Equipment for Construction Sites and Mines

When selecting fresh water distribution equipment for construction sites, mines or public works needs, make sure you check the water trailer specification to ensure that the product can stand up to the harsh conditions on your site. You want to make sure you understand how you will be filling and discharging the water trailer on a regular basis so you have the right configuration for your needs.