Choices for Agricultural Wastewater Pumps

With agricultural wastewater pumping needs, both government and industry have the challenge of finding pumping equipment that can handle chemical based wastewater like insecticides and PH balancing solutions plus wastewater manure, hair and other solids.

Sludge Handling Equipment Improvement Project – Municipal

When Wastecorp works with consulting engineers and operators on sewage treatment plant improvements, we look to limiting the footprint inside the plant due to the

Cool Waste Oil Collection Pumping System From Our Customers

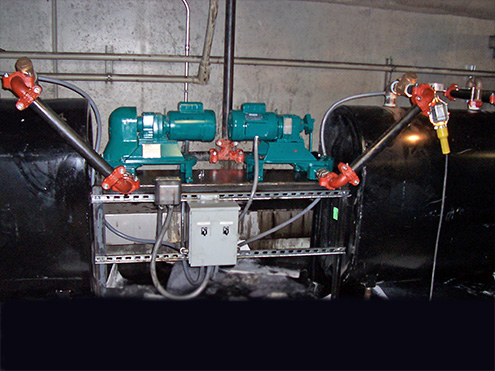

Mud Sucker 2FA Series Diaphragm pumps are known for their versatility for oil collection systems, especially waste trap grease, transmission fluids and motor oil. Many of our innovative customers also design their own collection systems. In the installation you see here, one customer used two Mud-Sucker 2FA-EC (electric) diaphragm pumps to set up a new waste oil collection system at a city bus depot. The bus depot collects motor oil and transmission oil in drain pans. The waste is then gravity fed into two, 275 gallon collection tanks, each tank having a pump and float system. The oil is then sucked up and discharged into a common 2″ riser travelling up 25 feet. The oil travels horizontally for 161 feet and then drops 25 feet into a larger storage tank. The suction and discharge height are well within the limits of these Mud-Sucker pumps.

Portable Waste Oil Recovery Pumps

Waste oil recovery and pumping is a hot topic right now in the world of pumps. For facilities with multiple storage tanks or sites, a portable pump may be a great option considering the alternatives. Traditionally vacuum pump trucks have been one of the only options available to transfer waste oil from tanks, cargo, tanker ships, on site storage facilities and more. This is no longer the case.

The Mud Sucker diaphragm pump system has a variety of sizes and options to transfer all kinds of waste oils no matter the size of the job or facility. For example, at this North American military base (pictured left), the customer uses Wastecorp’s Mud-Sucker 2F-MC diaphragm pump with wheel kit. This powerful pump is moved easily from site to site and transfers up to 25 GPM. With few moving parts and a contoured velocity channel, this pump is virtually maintenance free.

For large military bases with multiple locations including vehicle service area, aircraft hangers and even waste cooking oil, the Mud-Sucker 3F series (with a 3” connection) provides more pumping power with capabilities up to 80 GPM.

Speak to a waste oil

How to Plan a Marine Pump Out Station

What Does A Marine Pump Out Station Do?

A marine pump out station is a facility that allows for boat owners to pump out sewage from their boat’s holding tanks. Having a pump out station for boats is essential for maintaining clean waterways and preventing pollution.

Importance of Planning Your Marine Pump Out Station

Planning a marine pump out station ensures optimal functionality and waste management at your marina. The process involves knowing your marina’s available space, daily traffic and average vessel size to ensure you are getting the appropriate equipment. Consulting other marinas and marine pump experts ahead of when you actually need it installed can also provide valuable insights.

Wastecorp, a leading marine pump out manufacturer, has over the past few years observed an emerging trend: marinas experiencing increased boat and yacht traffic. In fact, it’s forecasted that the recreational boat market will reach USD 27.45 billion by 2030. As such, it’s crucial that your current marine pump out plan can also accommodate future growth effectively.

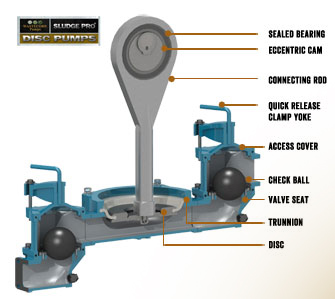

Compare Double Disc Pumps With Single Disc Pumps

Since we launched the Sludge Pro Disc Pump product line, there have been several questions as to whether or not a single disc or double disc pump is more appropriate for a specific wastewater treatment application.

To be clear, there is not always a need for a double disc pump, a single disc pump will fit the pump specification properly. One of the reasons why consulting engineers and contractors have put the double disc pump specification in place is because there has been few other alternatives.

Grout Pumps for Commercial and Residential Applications

As the weather improves for commercial grouting jobs it gives us an opportunity to address contractor concerns. One of the comments we heard from contractors who work with grouting jobs before the Sludge Sucker grout pump was made available, is that there was a lack of dependable, compact grout pumps that could easily be moved to job sites with tight spaces. Wastecorp went to work and designed/engineered the Sludge Sucker Professional Grout Pump. Now, this has not been featured on Shark Tank (yet) but we have been thinking about it due to its positive response from construction professionals. Since then, the Sludge Sucker has become a staple for commercial contractors and public works crews to grout door frames, pilings, slab jacking, void filling, mud jacking and many other commercial grouting applications.

New Grout Pump Crank Arm

Our 2nd generation Sludge Sucker has just been launched with exciting new components to enable long life cycle use.

The first major change is with the crank arm mechanism. The new grout pump crank arm has been designe

How to Pump Out and Have Potable Water With One Pump System

Hi, the DPW for LA City is looking for a more productive way to pump out septic waste and dirty standing water and then rinse the area after use. We would preferably want one pump and tank system to do the job.

Diaphragm Pump Design and Engineering

Wastecorp didn’t invent the diaphragm pump but when we introduced the Mud Sucker diaphragm pump product line almost 25 years ago we set out to innovate and radically transform how customers transfer fluids. One of our first Mud Sucker models, the 4BW-MDD Series is a walking beam style pump that uses a heavy duty piston motion to move heavier slurries found in coal mine, pulp and paper and municipal sewage applications. What makes this pump so special is its ability to transfer heavy solids with a choice of Siemens gear box and motor, gas or diesel engine (Yanmar diesel model shown).

Driving the Conversation in The Diaphragm Pump Business

The variety of pumping applications we see from the field grows everyday; From biodiesel production, bauxite, sugar refining to refineries and waste water treatment. And, each of these applications gets improved pumping performance with different components designed for specific applications. With Wastecorp’s flex-production floor, pump models like the 4BW-MDD can get stainless steel valve seats for customers who move corrosive fluids or FDA compliant internal coatings for customers in the food processing industry.

Wastecorp’s improved production efficiency gets translated into cost savings for the pump user in a variety of ways.

First, you get the pump you need without having to overkill your pump purchase with the traditional cook

Pumps in Upstate New York

It’s not often that we get to exhibit our wastewater pumps and systems so close to home. But during the week of April 14th Wastecorp will be exhibiting our new disc pumps, Mud Sucker Diaphragm pumps and Trash Flow Trash Pumps at the New York Rural Water Association annual technical conference at Turning Stone Casino in Verona, New York.