Industrial Wastewater Pumps – Case Study

Industrial companies looking to responsibly transfer waste oil and wastewater have found success with Wastecorp’s Mud Sucker 2FA Series diaphragm pumps. This

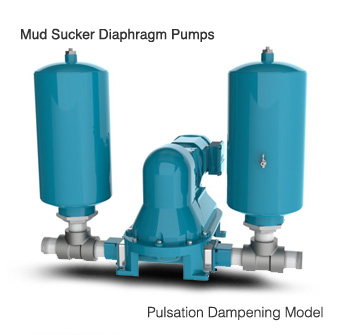

Pumps: How to Maintain a Continuous Flow and Minimize Pulsation

With pumping applications, one of the challenges you face especially when pumping thinner liquids, is to maintain continuous flow without “jerking the hose” or disruptions in pump productivity. One of the consulting engineering firms we have worked with in California illustrates this point well:

Primary Sludge Pumps at a WWTP

Primary sludge pumps are typically used in municipal Wastewater treatment facilities to transfer digested sewage and sludge. This is a broad pump category that encompasses positive displacement pumps to pump sludge in ranges usually up to about 500 GPM. The choices of pumps vary from double diaphragm pumps, plunger pumps, double disc pumps, rotary lobe pumps, progressive cavity pumps and more.

In todays pump marketplace, there are generally two schools that operators and consulting engineers follow when specifying primary sludge pumps. The first option is to install a more robust pump model with features like ball check technology to manage varying solids percentages or abrasive solids. These pumps typically cost a bit more to begin, but the spare parts costs are much lower down the road. Examples of such pumps are plunger pumps, double diaphragm pumps and double disc pumps.

Diaphragm Pumps Now Available With Control Panels

One of the trending customer requests this past year is custom diaphragm pump stations equipped with control panels and mobility options. To give you an example (and some ideas for your own pump application), one of our customers who happens to be one of the largest snack food producers globally, contacted Wastecorp’s engineering department asking for design proposals for a 3″ diaphragm pump out system complete with a mobility kit and the ability to directly control the pump operation. The diaphragm pump unit needed to be manufactured to maneuver easily on the factory floor aisles with custom dimensions. The pumps travel throughout the facility transferring chocolate based waste slurry and vegetable oil residues.

Look to the left and this is what our pump engineers came up with. This is the 3FA-EC diaphragm pump control panel model with e-stop, push bottom start and a specialized float system which detects when the pump should begin operating and automatically turn off. The customer ended up ordering 10 units for other facilities. The best part of this case study is that Wastecorp and our customer are in constant contact reviewing the benefits of the pump system and making design changes for future facility needs. We work one-on-one for custom results and constant improvement.

The Mud Sucker diaphragm pump with transformer you see here is designed with a more compact installation in mind. The customer ordered this Mud Sucker 3″ diaphragm pump for assembly line food processing waste transfer tasks. This unit transfers waste pit slurries and detects when the pit is empty or in need of pumping. The pump is

Diaphragm Pump Technology Advances

Diaphragm pump technology for wastewater pumping, waste oil, septic and food processing applications has advanced. Wastecorp, a designer and manufacturer of diaphragm pumps, has invested in R&D to build better diaphragm pumps. Wastecorp’s vision is to become the worldwide leader in diaphragm pump technology and reaching this goal is becoming closer for the company every year.

At the heart of the latest diaphragm pump technology update is “quick release yoke technology” The principle here is to make it easier for the operator of the pump to conduct routine maintenance. Quick release technology has been available up until this point on the Mud Sucker premium B Series professional line. This type of diaphragm pump uses ball valves or check ball technology to move wastewater. However, in 2020, the Mud Sucker FA Series diaphragm pump is also available with quick release technology.

The diaphragm flapper material is a severe duty rated elastomer for waste oil pumping and general wastewater pumping applications. You can also pump select corrosive fluids with this diaphragm pump but should check with the factory with your application first.

In the photo above, you see the new diaphragm pump, Mud Sucker model read more

Grout Pumps for Commercial and Residential Applications

As the weather improves for commercial grouting jobs it gives us an opportunity to address contractor concerns. One of the comments we heard from contractors who work with grouting jobs before the Sludge Sucker grout pump was made available, is that there was a lack of dependable, compact grout pumps that could easily be moved to job sites with tight spaces. Wastecorp went to work and designed/engineered the Sludge Sucker Professional Grout Pump. Now, this has not been featured on Shark Tank (yet) but we have been thinking about it due to its positive response from construction professionals. Since then, the Sludge Sucker has become a staple for commercial contractors and public works crews to grout door frames, pilings, slab jacking, void filling, mud jacking and many other commercial grouting applications.

New Grout Pump Crank Arm

Our 2nd generation Sludge Sucker has just been launched with exciting new components to enable long life cycle use.

The first major change is with the crank arm mechanism. The new grout pump crank arm has bee

Diaphragm Pump Design and Engineering

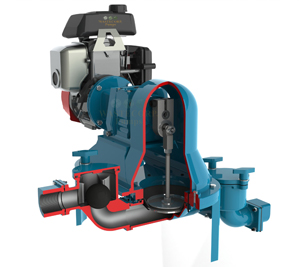

Wastecorp didn’t invent the diaphragm pump but when we introduced the Mud Sucker diaphragm pump product line almost 25 years ago we set out to innovate and radically transform how customers transfer fluids. One of our first Mud Sucker models, the 4BW-MDD Series is a walking beam style pump that uses a heavy duty piston motion to move heavier slurries found in coal mine, pulp and paper and municipal sewage applications. What makes this pump so special is its ability to transfer heavy solids with a choice of Siemens gear box and motor, gas or diesel engine (Yanmar diesel model shown).

Driving the Conversation in The Diaphragm Pump Business

The variety of pumping applications we see from the field grows everyday; From biodiesel production, bauxite, sugar refining to refineries and waste water treatment. And, each of these applications gets improved pumping performance with different components designed for specific applications. With Wastecorp’s flex-production floor, pump models like the 4BW-MDD can get stainless steel valve seats for customers who move corrosive fluids or FDA compliant internal coatings for customers in the food processing industry.

Wastecorp’s improved production efficiency gets translated into cost savings for the pump user in a variety of ways.

First, you get the pump you need without having to overkill your pump purchase with the tradi

Wastecorp Keeps Pumping Through New England Storm

The show was to kick off Wastecorp’s 2015 promotional campaign with its Sludge Pro Double Disc Pumps, Mud Sucker Diaphragm Pumps, Trash Flow Trash Pumps and Sludge Master Plunger Pumps. The NEWEA annual conference in January involves many of Wastecorp’s nearby Wastewater Treatment Facilities in Plymouth, Providence, City of Boston, Sandwich, City of New Haven