Wastecorp has published a double disc pump comparison guide for consulting engineers, end users and pump distributors. This resource explains the difference between two different pump types and the methods each use to pump sewage, sludge and wastewater. You can download this comparison guide by clicking here or continuing to read below.

Who is Wastecorp?

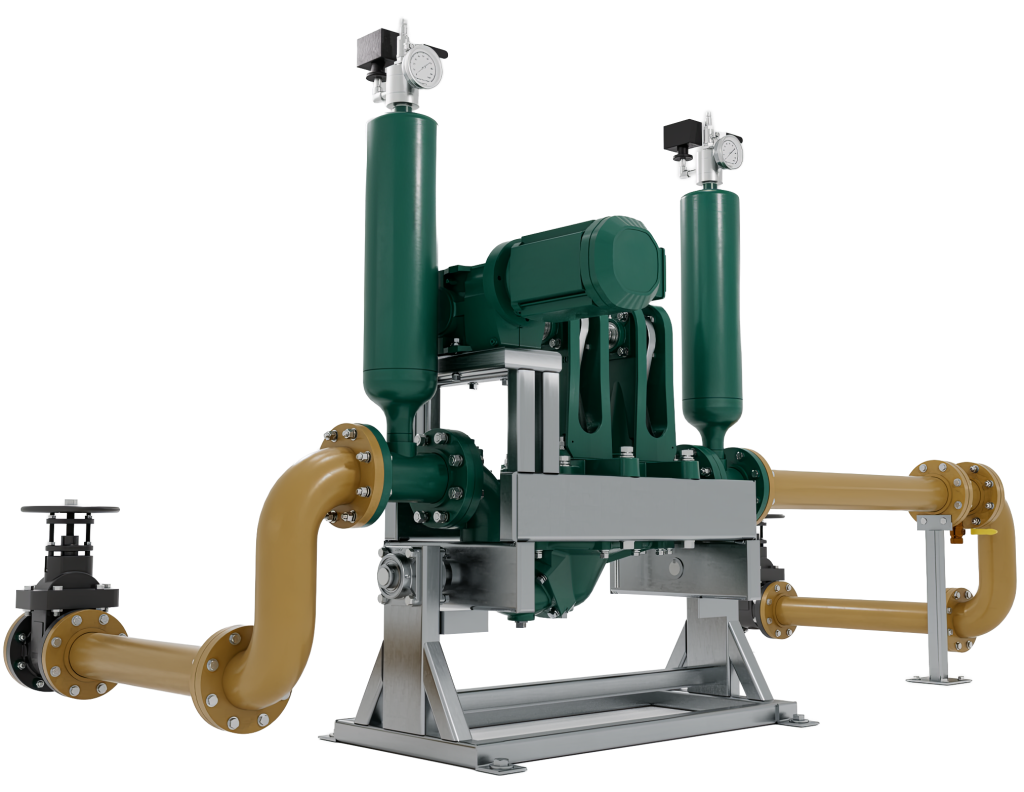

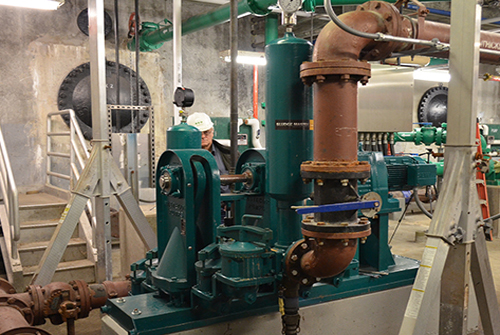

Wastecorp Pumps is an ISO 9001 and ISO 14001 certified pump manufacturer. Wastecorp manufactures the Sludge Pro brand double disc pump. The company specializes in sewage pump and wastewater pump manufacturing. This includes multiple products for municipal/industrial applications. Wastecorp has manufactured pumps since 1993 in the United States and Canada. Information about Sludge Pro Double Disc Pumps can be found at

https://wastecorp.com/Products/Disc-Pumps

What is a Penn Valley Pump (PVP)?

The Penn Valley pump is a diaphragm pump. PVP has fully acknowledged this in their patent # US 7,559,753 B2. The patent references George Burrage’s (a family member of PVP President) patent application # GB 2013287A as the basis of construction for the PVP pump. Nowhere in GB 2013287A does it reference a disc at all. This legal document fully acknowledges the fact that the Penn Valley pump is a diaphragm pump. PVP also references the use of diaphragms in all of their trademark registrations.

What is The Difference Between Penn Valley (PVP) and Sludge Pro Pumps?

Sludge Pro double disc pumps are available with either a clack valve or a ball valve configuration. The operator selects one or the other. As of 2017, Penn Valley only offers a clack valve. The Sludge Pro double disc pump is the only manufacturer that includes either a manual or hydraulic jack to raise the upper body of the pump to perform maintenance while standing. In most cases, the Penn Valley operator must crawl below heavy castings to perform maintenance. Penn Valley pumps also use a short stroke length, requiring the pump to run at much higher rpm speeds. PVP acknowledges that this can reduce the operating life of the pump. This is particularly true in grit / sand or abrasive sludge’s. In these situations, PVP recommends supplying hardened housings so the check valve does not wear out the casting when seating. When this happens, the entire pump body may require replacement or refurbishment. A primary problem with the PVP design is that debris can collect under the check valve which can prevent the valve from sealing and cause “dewatering”. If this happens, PVP acknowledges that the pump needs to be “flushed with water to clear any debris”. Since there is no access cover to the pump internals, the operator must usually disassemble the pump to access lodged debris. PVP also acknowledges that in some types of Sludge pumping applications with over 6% solids – may cause pump cavitation.

Are Parts for Sludge Pro Double Disc Pumps Available Within 24 hours?

Yes. Wastecorp can send any parts for your double disc pump for delivery within 24 hours in most areas of Canada and the United States. In select areas, Sludge Pro parts are stocked in the State/Province or county that the pump are located in.

Are Double Disc Pumps Maintenance Free?

While double disc pumps require no regular maintenance, all mechanical equipment requires some maintenance in their life. Double disc pumps are no different. Periodic replacement of the trunnion, disc and other components may be required.

Is The Sludge Pro Double Disc Pump Design Patented?

Yes. Wastecorp’s double disc pump design is patented.

Is “Double Disc Pump” a Trademark?

No. The United States Patent and Trademark office on multiple occasions has denied Penn Valley Pump Company’s application to trademark the term double disc pump and ruled that double disc pump is a generic term in the marketplace (term of art) used in the pump industry.

Is There an Online Video Showing The Differences Between Penn Valley and Sludge Pro?

Yes. visit: https://www.youtube.com/watch?v=kDyt6_u1sKc

A more detailed comparison between pumps is available in the Double Disc Pump Comparison Guide for consulting engineers, operators and pump distributors. This guide is updated as new information becomes available. If you have any questions about your double disc pump project contact Wastecorp for more information at 1-888-829-2783 or info@wastecorp.com