In a world of increasing water scarcity, wastewater management has become crucial to limiting the adverse effects of climate change and population growth. Purifying wastewater allows us to conserve [...]

Why Mudsucker Diaphragm Pumps Are Ideal for Wastewater Treatment

Pumps for Car Wash Waste Pit Removal

One of the most popular pumps for waste pit pumping is the Mud Sucker 2FA-M Series. With a 20 GPM transfer capability this pump is great for car wash waste.

read morePumps For Vertical Farming Operations – What You Should Know

Growing vegetables and leafy greens vertically indoors is one of the hottest trends in agriculture right now. Having freshly grown greens in urban areas, close

read moreIndustrial Water and Waste Oil Pumping for Railroads

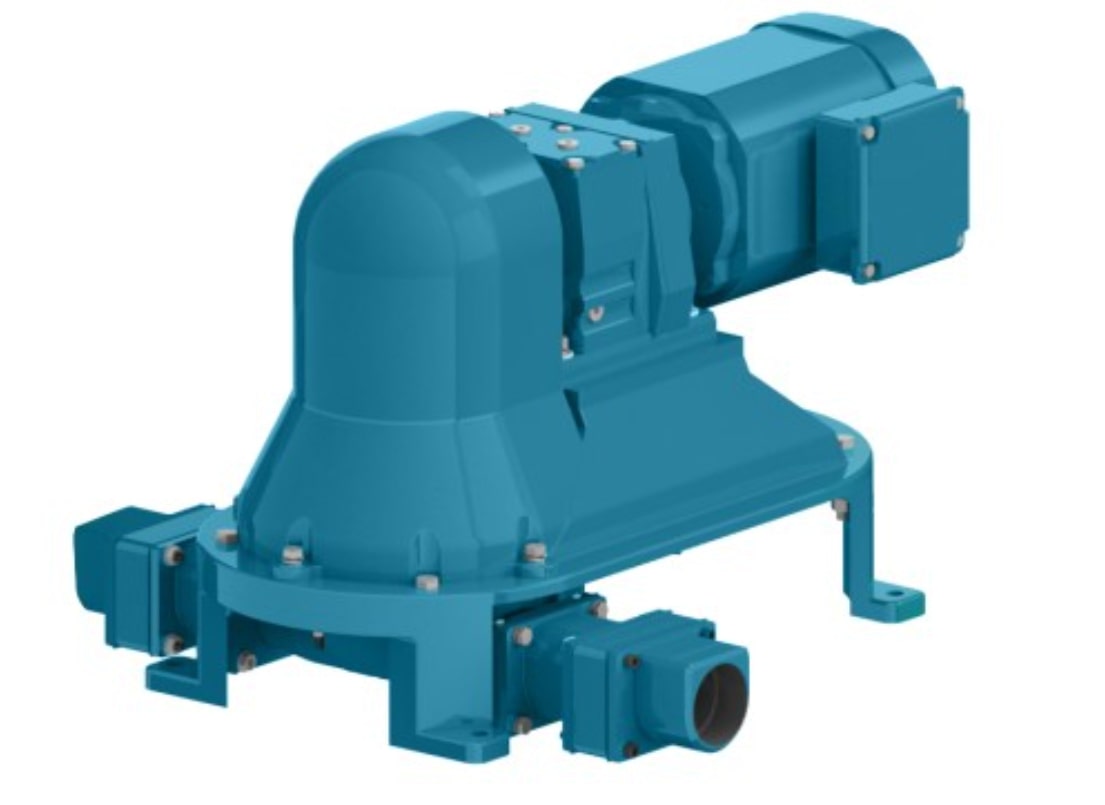

Electric Diaphragm Pump for Railways. Mud Sucker 2B Series, Manufactured by Wastecorp

One of the questions we get most often from railroads is how to cost effectively

What is a Low Shear Pump?

Low shear pump for municipal and industrial pumping.

One of the topics that we often review at Wastecorp is customers requesting low shear pumps that don’t completely

Pump Out Systems to use in Underground Parking Garages

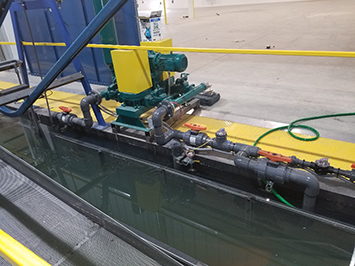

Super Duty Vacuum Pumps For Underground Parking Garages

Pump out service companies working in parking garages face unique challenges in getting a professional

read morePumping Out Tanks With Diaphragm Pumps

You name the tank that needs to be pumped out and we have heard of at least a few customer applications that correspond with that tank. Underground septic tanks, lagoon transfer, transport truck tankers, locomotive tankers, waste pits and waste vegetable oil drums are among the most popular. What you have to keep in mind is that in most of these applications, you will need a pump that can easily maneuver in areas to access the discharge valve or at least some place where you can place the suction hose.

WWTP Expands in New York Led by Arcadis Engineers, Kiewit Contractors, Siewert Equipment, Jett Industries and Wastecorp Pumps

New Wastewater Treatment Upgrades

An upgraded Wastewater Treatment Plant in New York State is well on its way to becoming an advanced wastewater pumping and treatment center for a rapidly developing area. Among the changes include new [...]

read moreWhy Do Some Water Trailers Have Black Tanks?

One of the most popular questions customers ask when trying to find the right water trailer for their needs is why do some water trailers have black or green tanks?