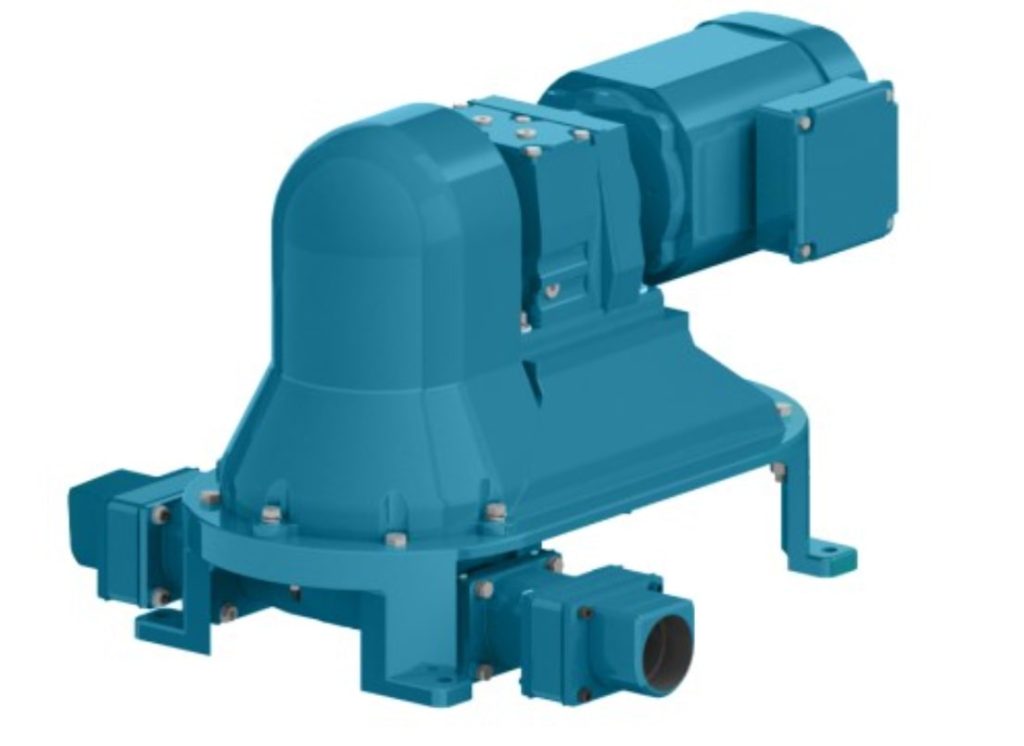

Do you need to adjust the speed of your pump’s electric motor, modulating the power being delivered? We’ve got good news; all Mud Sucker diaphragm pump models are now available with a variable frequency drive (VFD).

-

- VFD’s

help to accommodate fluctuating demand by adjusting pump energy consumption and costs by adjusting the amount of power delivered to the motor for pumping specific tasks.

Public utilities and industrial fluid handling facilities are increasingly specifying pumps with VFD’s to reduce maintenance costs and energy consumption. Since not all pumping jobs are alike, the pump adjusts the power being delivered when handling higher than normal levels of slurry, mud, raw sewage, water and more.

The advantages of a VFD for a pump drive system reduce the abrupt start up that typical electric drives experience when first starting the pump. VFD’s allow for a slow start up, gradually increasing the amount of power needed for the job. Pump components experience less stress with a slower start up, thus increasing component life by up to 40%. VFD’s also allow for more control over processes such as wastewater transfer, water distribution, aeration and chemical transfer. Energy costs average 30-50% lower than a standard electric pump motor, so the savings can be significant. While the initial cost of a VFD may be 30% higher than a standard high performance motor, the long term maintenance and energy savings more than make up for it.

Learn more about how a VFD for your Mud Sucker diaphragm pump can get you pumping smarter. Contact a Wastecorp pump specialist today at 1-888-829-2783 or email dstarr@wastecorp.com