How to Select Your Farm or Ranch Pump System

No one can argue that having a simple diaphragm pump for farm and ranch applications can some times be a lifesaver and time saver. Whether you’re pumping manure, silt from a pond, fruit juice or vegetable matter and more,having a trusted pump by your side can mean the difference between having aconsistently reliable pump and one that is nothing but hassles or in need of repair. Troy from Sandusky Ohio, has been a farmer in the area for decades.Here’s part of the discussion we had with him about his pumping needs and some recommendations we made:

Exploring Diaphragm Pump Components: A Guide to Chemical Compatibility

Diaphragm pumps have become critical to many industries thanks to their versatility and durability. For a diaphragm pump to perform optimally, however, care must be taken during the materials of construction [...]

The Dynamic Role of Diaphragm Pumps in the Food & Beverage Industry

Modern food production demands safety and efficiency in all of its processes. During every step of production, preventing contamination and waste is crucial to delivering a product that maintains consumer [...]

Choosing the Right Pump: Diaphragm Pump vs. Piston Pump

Piston pumps and diaphragm pumps are used for similar applications, particularly agricultural spraying. However, there are many important differences between these types of pumps to consider before [...]

What’s the Difference Between Diaphragm Pumps & Centrifugal Pumps?

As the two most common types of pumps on the market, diaphragm pumps and centrifugal pumps are both great choices for a variety of applications, including liquid [...]

Aod Pumps: Repair it or Replace it?

Aod pumps. They have been around for years for pumping everything from wastewater to oil slurry to sludge. Almost every pump distributor out there has either pushed Wilden, Sand Piper or some other air operated diaphragm pump option at least historically any way. As these pumps age, end users and operators have the issue to grapple with: do I repair my AOD pump or do I replace it? Can I still tolerate my energy bill from Aod pumps or is there a viable alternative? A well known defense contractor pondered these questions and more with a query to Wastecorp’s pump engineering dept.

“We are using Aod pumps side by side at our manufacturing facility to pump jelly type slurry wastewater and waste oil or a combination of that. These AOD pumps are costing us $1000 to $2000 a piece to rebuild. They provide poor performance and the energy costs are ridiculous. This is the 21st century, there has to be a better a

Pulp and Paper Process Pumps and You

Pulp and paper processors, saw mills and carton companies have a challenge in finding the right pumping equipment for various parts of their processes. Mineral processing, log washing, fan pumps, effluent sumps and hot pond transfer are just some of the pump applications faced by this industry. Operators often do not have all the information needed to select the right size and style of pumps needed for this variety of pumping needs around their facility.

Marty G. is the senior operator at a paper mill along Wisconsin’s Fox River, which hosts one of the highest concentrations of pulp and paper facilities in the US. Wastecorp work

How to Find New Diaphragms for an Old Diaphragm Pump

One of the frequent calls we hear from customers is that they either have an older diaphragm pump make or need replacement diaphragms for their newer diaphragm pump. Some genuine replacement parts are easier to find than others. The good news is that replacement diaphragms and other parts for almost any kind of diaphragm pump are available for pumps dating back as far as the 1940’s.

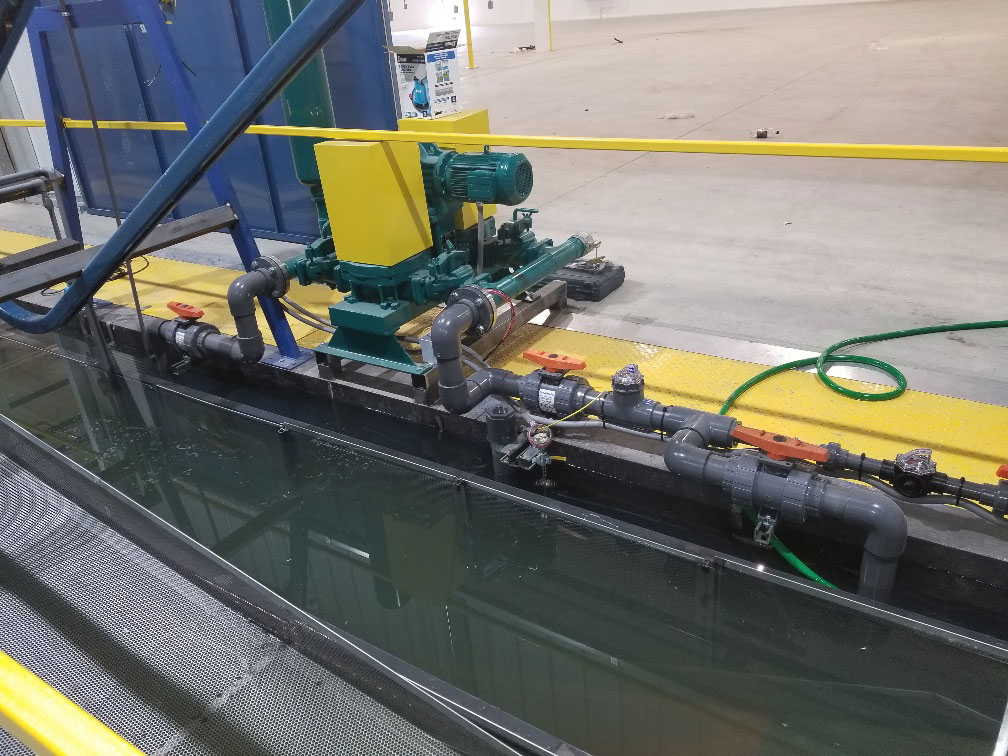

Diaphragm Pump for Sewage Pumping

If your pump project calls for primary sludge pumps under 220 GPM, the Mud Sucker Double Diaphragm pump is something you should consider for municipal sewage and industrial sludge pumping applications.

Case in point: A Northeast urban wastewater treatment plant upgrade and expansion recently

specified and installed two Mud Sucker 3B-EC-DD Series double diaphragm pumps with one and three quarter inch solids handling capabilities These Mud Sucker’s pump primary slud

Waste Oil and Wastewater Pumps for the Natural Gas Industry

Honey wagon waste containment systems are used across a wide range of industries and have endless application uses. Waste containment systems are used to pump out wastewater, oil or septic waste from storage tanks, lagoons, barrels and more. The national gas industry requires honey wagons as well. From natural gas well process uses, wastewater containment and facilities management, portable waste containment systems play a valuable role in collecting wastewater and safely transporting is to an environmentally responsible dump station. With the advent of fracking, our customer base for waste containment systems in New York State, PA, Virginia and Kentucky has rapidly expanded. Dustin R, from Lexington, KY recently contacted Wastecorp about a new pump out system for his Natural gas company:

“We are looking for a mobile tank system to drain used oil tanks. The pump we would like to use is an air driven diaphra