Pulp and paper processors, saw mills and carton companies have a challenge in finding the right pumping equipment for various parts of their processes. Mineral processing, log washing, fan pumps, effluent sumps and hot pond transfer are just some of the pump applications faced by this industry. Operators often do not have all the information needed to select the right size and style of pumps needed for this variety of pumping needs around their facility.

Marty G. is the senior operator at a paper mill along Wisconsin’s Fox River, which hosts one of the highest concentrations of pulp and paper facilities in the US. Wastecorp worked with Marty and his company to size the correct pump for hot pond pumping. See his initial questions on the application below:

“Our paper mill has a hot pond where we collect process wastewater in the basement. We need a pump that can transfer this wastewater along with some solids (bark, wood pieces, etc. but not more than ½” in size). We also want the pump to be connected to a 575-volt starter and have float switches to automatically start and stop the pump when the tank reaches predetermined levels. What do you suggest?”

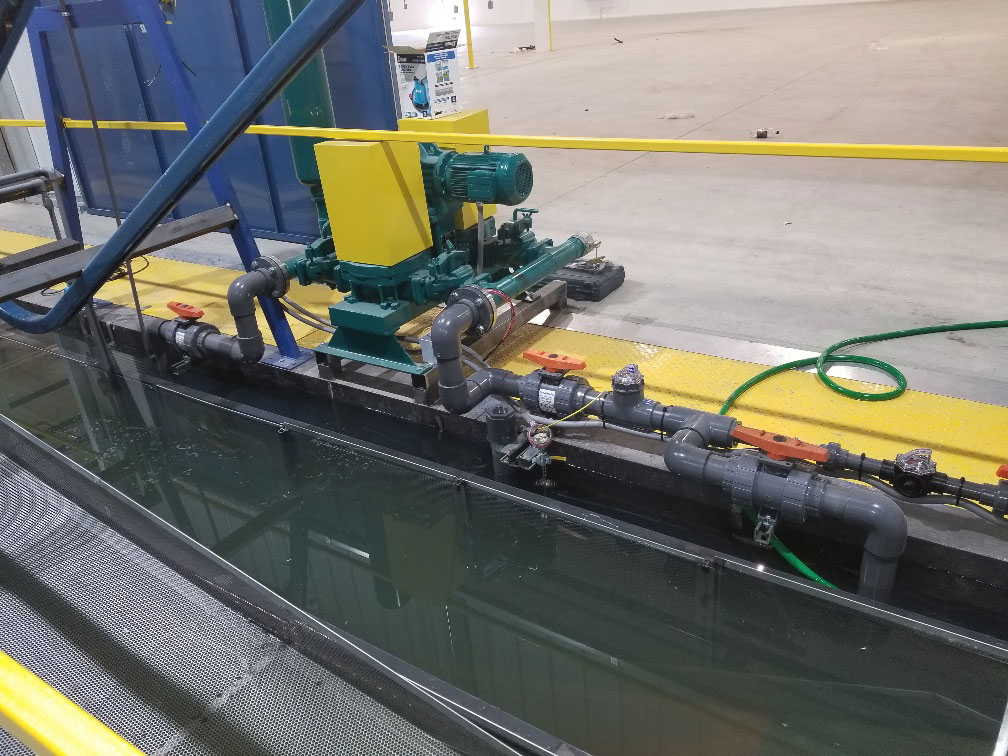

Wastecorp went right to work for Marty and we designed the pump system you see in the photo above. First, since the flow rate required was under 20 GPM, Wastecorp recommended the Mud Sucker 2FA-EC with a patented contoured velocity channel to help move the wood chips, bark and other slurries when needed. Second, we supplied an NEMA 4, 575-volt control panel to enable the auto-start/stop function with the float switch. This includes enhanced safety options like alarms for monitoring pump performance. Wastecorp also included mounting brackets and hardware custom made for Marty’s sump area. Third, Wastecorp supplied 10 amp/120 VAC float switches to monitor tank levels and automate the pumping process.

While applications for pumping can get complicated, it’s always helpful to work with a pump company that can custom engineer your entire pumping system, from the control panels to the accessories you need. It saves you time, hassles and provides you with the comfort that professionals have designed your entire pump