Diaphragm Pump for Sewage Pumping

If your pump project calls for primary sludge pumps under 220 GPM, the Mud Sucker Double Diaphragm pump is something you should consider for municipal sewage and industrial sludge pumping applications.

Case in point: A Northeast urban wastewater treatment plant upgrade and expansion recently

specified and installed two Mud Sucker 3B-EC-DD Series double diaphragm pumps with one and three quarter inch solids handling capabilities These Mud Sucker’s pump primar

How to Change The Disc Assembly on A Double Disc Pump

When Wastecorp designed the Sludge Pro Double Disc Pump we set out with the goal to engineer the easiest to service sewage pump available to engineers and WWTP end users. One common request from the engineering community was that an operator or maintenance person would never have to crawl under a double disc pump with a casting hanging overhead and the potential for sewage to leak over the operator. When you think about – why would anyone design a pump like that? Our answer is that you would have to ask the competitor because Wastecorp would not.

The video below shows how to change the trunnion on a Sludge Pro double disc pump. As you can see most of the maintenance is done with the operator standing up and most components visible to the operator.

Safety First

Changing the disc assembly on a Sludge Pro double disc pump is a simple process which can usually be done within 30 minutes

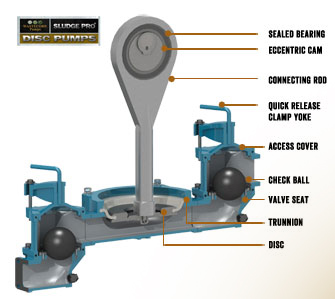

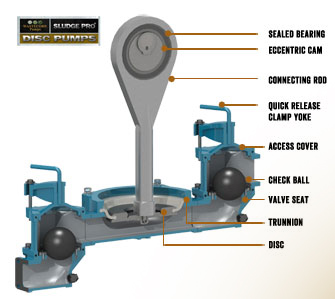

How a Double Disc Pump Works

We have all seen the outside of a double disc pump but rarely do we see what makes the pump actually work. Just to review, a double disc pump is a positive displacement pump that uses a trunnion (elastomer), a disc and a connecting rod to force sewage from the suction side to the discharge side of the pump by creating a vacuum inside the pump body. The valve chambers with the black check valves you see in the photo help to manage higher than normal concentrations of grit and solids in municipal wastewater.

Orange County Waste Acceptance Facility Looks for Pump Solutions

Orange county is home to dozens of resorts, hotels and theme parks which generate tens of millions of gallons of wastewater that needs to be treated every year. When an Orlando, Florida renewable energy company earned a multiyear contract to accept waste from local resorts and theme parks, they needed severe duty pumps to transfer thick slurries and solids.

The details of the project called on the requirement of pumps to transfer ground up seafood shells, grease trap waste, utensils, animal renderings, wastewater and more. In this application, the waste is unloaded from a tanker into a waste pit. The waste is then transferred to a conveyor system which then separates most of the foreign objects like utensils, large solids, plastic bags and more. The remaining waste is sent through the Sludge Master plunger pump and then to the digesters of the wastewater treatment plant. With millions of people visiting Orlando resorts and theme parks every year, this amounts to a lot of waste, as tanker trucks deliver new loads of slurry like liquid waste around the clock.

Working with Wastecorp, the company decided on a Sludge Master PE 942 with a 20 hp motor and mechanical force feed oile

Primary Sludge Pumps at a WWTP

Primary sludge pumps are typically used in municipal Wastewater treatment facilities to transfer digested sewage and sludge. This is a broad pump category that encompasses positive displacement pumps to pump sludge in ranges usually up to about 500 GPM. The choices of pumps vary from double diaphragm pumps, plunger pumps, double disc pumps, rotary lobe pumps, progressive cavity pumps and more.

In todays pump marketplace, there are generally two schools that operators and consulting engineers follow when specifying primary sludge pumps. The first option is to install a more robust pump model with features like ball check technology to manage varying solids percentages or abrasive solids. These pumps typically cost a bit more to begin, but the spare parts costs are much lower down the road. Examples of such pumps are plunger pumps, double diaphragm pumps and double disc pumps.

Compare Double Disc Pumps With Single Disc Pumps

Since we launched the Sludge Pro Disc Pump product line, there have been several questions as to whether or not a single disc or double disc pump is more appropriate for a specific wastewater treatment application.

To be clear, there is not always a need for a double disc pump, a single disc pump will fit the pump specification properly. One of the reasons why consulting engineers and contractors have put the double disc pump specification in place is because there has been few other alternatives.

Double Disc Pump Comparison Guide for Engineers, Operators and Pump Distributors

Wastecorp has published a double disc pump comparison guide for consulting engineers, end users and pump distributors. This resource explains the difference between two different pump types and the methods each use to pump sewage, sludge and wastewater. You can download this comparison guide by clicking here or continuing to read below.

Who is Wastecorp?

Wastecorp Pumps is an ISO 9001 and ISO 14001 certified pump manufacturer. Wastecorp manufactures the Sludge Pro brand double disc pump. The company specializes in sewage pump and wastewater pump manufacturing. This includes multiple products for municipal/industrial applications. Wastecorp has manufactured pumps since 1993 in the United States and Canada. Information about Sludge Pro Double Disc Pumps can be found at

https://wastecorp.com/Products/Disc-Pumps

What is a Penn Valley Pump (PVP)?

The Penn Valley pump is a diaphragm pump. PVP has fully acknowledged this in their patent # US 7,559,753 B2. The patent references George Burrage’s (a family member of PVP President) patent application # GB 2013287A as the basis of construction for the PVP pump. Nowhere in GB 2013287A does it reference a disc at all. This legal document fully acknowledges the fact that the Penn Valley pump is a diaphragm pump. PVP also references the use of diaphragms in all of their trademark registrations.

What is The Difference Between Penn Valley (PVP) and Sludge Pro Pumps?

Sludge Pro double disc pumps are available with either a clack valve or a ball valve configuration. The operator selects one or the other. As of 2017, Pe

Wastecorp Keeps Pumping Through New England Storm

The show was to kick off Wastecorp’s 2015 promotional campaign with its Sludge Pro Double Disc Pumps, Mud Sucker Diaphragm Pumps, Trash Flow Trash Pumps and Sludge Master Plunger Pumps. The NEWEA annual conference in January involves many of Wastecorp’s nearby Wastewater Treatment Facilities in Plymouth, Providence, City of Boston, Sandwich, City of New Haven