Waste trap grease pumps for commercial applications can be used for a wide variety of applications involving pumping grease from the source to a suitable treatment area. One such pump for pumping waste trap grease is the Mud Sucker Diaphragm pump which is used in shopping centers, hospitals, school cafeterias, restaurants, prisons and other government institutions where pumping grease for treatment is required.

For example, an engineer in Miami, Florida was tasked with designing a pump system for a large mixed use shopping center with restaurants and other attractions that involve pumping from grease pits to a collection area. The challenge was configuring the piping through the multi-level shopping center which was under construction and meeting city bylaws for proper waste trap grease treatment. The engineering firm and the contractor contacted Wastecorp to inquire about the Mud Sucker Diaphragm Pump’s track record in grease trap waste pumping.

How to Position Waste Trap Grease Pumps

Using CAD and Solid Works, Wastecorp’s grease pump engineering team worked with the consulting engineer and contractor to locate the pumps in the parking area. Since the shopping center was targeted for an upscale shopping experience, the pumps were surrounded by gates and an aesthetically pleasing enclosure to minimize the public’s exposure to such pumping equipment. The goal was for the public to not even notice the grease trap pumps.

Grease Pumps Selection

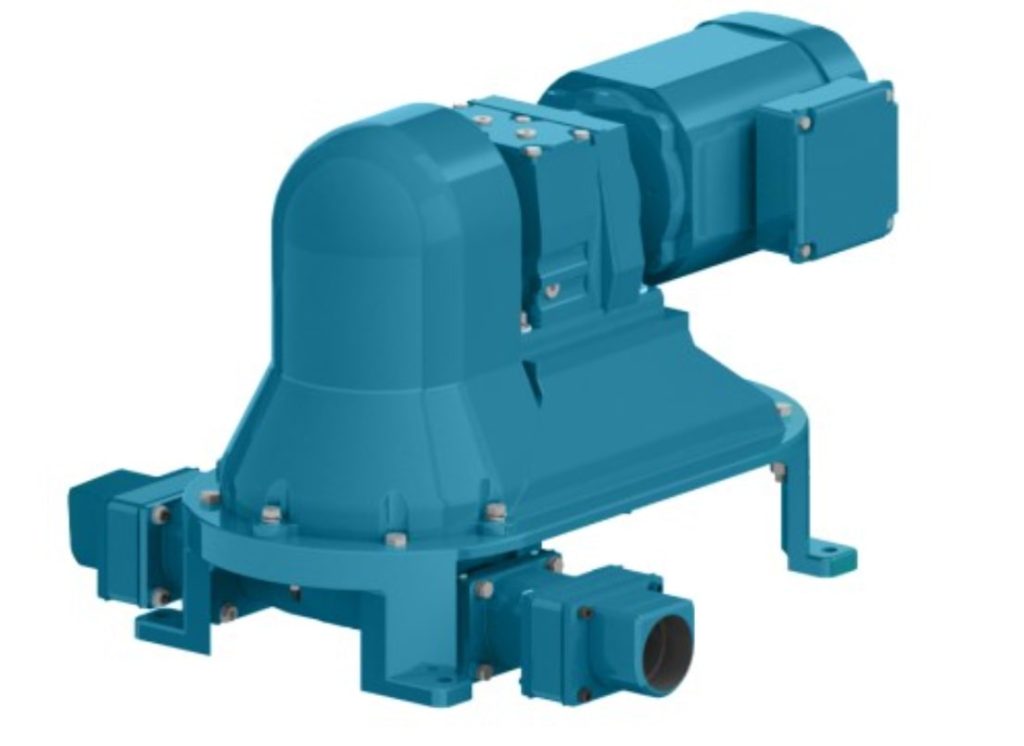

The engineer specified Wastecorp Mud Sucker 4B Series diaphragm pumps as the preferred grease trap pump for this project since this pump has an established history and good track record for this application.

It is also extremely easy to use, with minimal maintenance and easy to service components. One of the only major wear items is the diaphragm itself which can be changed easily and is not expensive. With service, available in all South Florida including Miami, the facility has the peace of mind that Wastecorp would provide whatever support is required throughout the lifecycle. Wastecorp also has a manufacturing and service network throughout the United States and Canada

Control Panels and Float Switches For The Pumps

Wastecorp also designed an integrated control panel system for the pumps to have an auto on/off function when the float level indicators show that the grease pits needed to be emptied. The pumps turn on when the grease pit is full and turn off when they are empty leading to energy savings and a more efficient pump operation. The control panel includes sensors that tell maintenance crews and pump operators when there may be an over pressurization event such as a blockage in the line or a possible closed valve. An alarm sounds in such an event and the pumps shut down to prevent damage to the pumping equipment. The Mud Sucker diaphragm pump is a positive displacement pumps and therefore must not operate against a closed valve which is called dead heading a pump in the industry.

Grease Pump Installation and Training

When it came time to install and start – up the pumps for operation, Wastecorp sent factory representative to the site to provide training to maintenance crews and the contractor. The Miami installation involved four pumps for two separate grease trap waste pits. The idea was to have one pump in operation and one backup pump in case of failure or servicing. This ensures a consistent operation with no disruption. Training included providing a recommended spare parts list to have on hand and recommended maintenance procedures. The local Wastecorp representative also made it clear that support was available locally when they needed it.

For a local waste trap grease pump consultation is your area you can reach a pump expert at 1-888-829-2783.