As the weather improves for commercial grouting jobs it gives us an opportunity to address contractor concerns. One of the comments we heard from contractors who work with grouting jobs before the Sludge Sucker grout pump was made available, is that there was a lack of dependable, compact grout pumps that could easily be moved to job sites with tight spaces. Wastecorp went to work and designed/engineered the Sludge Sucker Professional Grout Pump. Now, this has not been featured on Shark Tank (yet) but we have been thinking about it due to its positive response from construction professionals. Since then, the Sludge Sucker has become a staple for commercial contractors and public works crews to grout door frames, pilings, slab jacking, void filling, mud jacking and many other commercial grouting applications.

New Grout Pump Crank Arm

Our 2nd generation Sludge Sucker has just been launched with exciting new components to enable long life cycle use.

The first major change is with the crank arm mechanism. The new grout pump crank arm has been designed with a support beam and dual action lever. This assists the user with pumping thicker grouts with higher solids content. Instead of a single casting crank arm on previous models, the new dual action lever is 45% stronger and can outlast the most punishing of jobs.

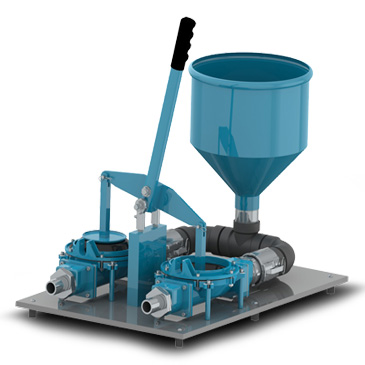

Double Diaphragm Grout Pumps

The second major change in grout pumps is the launch of the new Sludge Sucker Double Diaphragm Grout pump. This unique design doubles your output capacity when filling voids or tunnel linings in larger public works jobs or commercial grouting applications. The double grout pump sits on a high density polypropylene mobility slab for extra stability during grouting. The all aluminum frame make transporting the sludge sucker lighter and easier to maneuver.

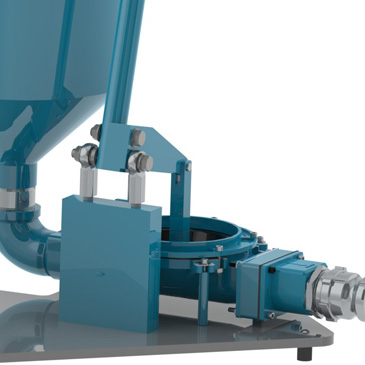

Door Jacking Grout Pumps

The third major change in grout pumps is the introduction of the door frame grout pumping system. This kit features industrial grade hosing to transport the grout through the injection points on the space bar. The best part is that the kit can be removed and you can use your single or double diaphragm grout pump for other grouting jobs around your work site.

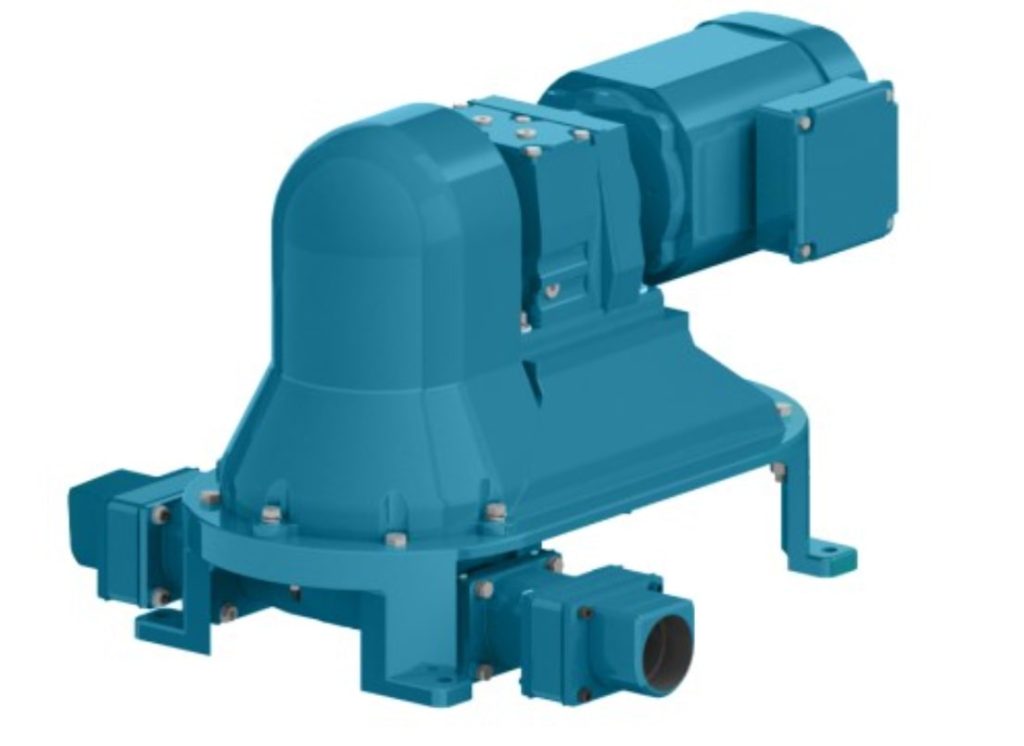

Pneumatic Grout Pumps

For contractors that have access to air hose lines, the Sludge Sucker Grout Pump is now available with air operated drive systems to move grout from the hopper to your injection points. You have a choice of single or double diaphragm models and custom hose packages to make the Sludge Sucker conform to your job site needs.