Wastecorp Mud Sucker Pumps Available With Variable Frequency Drives (VFD’S)

Do you need to adjust the speed of your pump’s electric motor, modulating the power being delivered? We’ve got good news; all Mud Sucker diaphragm pump models are now available with a variable frequency drive (VFD).

-

- VFD’s

help to accommodate fluctuating demand by adjusting pump energy consumption and costs by adjusting the amount of power delivered to the motor for pumping specific tasks.

Public utilities and industrial fluid handling facilities are increasingly specifying pumps with VFD’s to reduce maintenance costs and energy consumption. Since not all pumping jobs are alike, the pump adjusts the power being delivered when handling higher than normal levels of slurry, mud, raw sewage, water and more.

Dredging Pump Projects Made Easier

With dredging applications, Wastecorp generally encounters at least a few different kinds of projects: city or town sanctioned projects that are part of waterway management programs and private projects that include beautification, enhanced recreational access and improved appearance. For public projects, we generally work with engineering

A New Direction in Plunger Pumps: Sludge Pumping Capabilities With A Cleaner Design

When consulting engineers’ and facility operators begin to plan an upgrade for their sewage treatment plants most are considering four primary pumps: Plunger pump technology, rotary lobe pumps, progressive cavity and double disc pumps.

How to Pump Out Waste Oil

Pumping out waste motor oil, gear oil and other fluids like coolant, and grease can be easy for auto repair jobs, boat service and repair and tractor service for farms and utility vehicles. The Wastecorp waste collection systems store old engine fluids in a waste tote tank and can be outfitted with mobile systems like the model you see here.

Sludge Pumping in New York With Sludge Master Plunger Pumps

Pumping sewage for a city of over eight million people can be a challenging task and that’s exactly what the City of New York and surrounding communities like Westchester County must contend with. Wastecorp completed a plunger pump sludge moving project for the Ossining Waste Water Treatment Plant; a facility located about 30 miles from Manhattan and within walking distance to Sing Sing Correctional facility. Wastecorp’s plunger pumps were approved by GHD Consulting Engineers. Mace Contracting completed the installation. See video

Ossining replaced two existing plunger pumps with next generation Wastecorp Plunger Pumps HPE Series -triplex model HPE 1142. The pumps are designed to transfer thickened sludge to loading trucks that haul it away for sanitary treatment. The pumps feature heavy duty 11” plungers with a guided stuffing box system to reduce wear on the packing, plungers and connecting rods read more about the guided stuffing box system.

Part of Wastecorp’s onsite activities included our extensive classroom training program for facility maintenance staff. Plunger pump training helps staff to optimize performance of the pumping equipment and makes regular maintenance easier, quicker and safer. During the presentation staff learned how to service major components of the pumps including replacing t

The Problem of Space Constraints at Wastewater Treatment Plants

a Memphis, Tennessee area sewage treatment plant which recently installed a Space Saver after trying double disc and progressive cavity pumps

Questions: How to Plan a Pump Out for a Larger Marina

When it comes time to plan a new marina pump out system, many customers understandably find it challenging to know where to begin. Some have an idea of what kind of pump they need but aren’t sure about how to configure the pumps and piping. Throw in other elements like pumping up on an incline and it can get tricky. John S. operates a marina in Washington State and he posted the following question in our forum:

Q: “I need to outfit our 200 slip marina with new pump stations with one larger pump to feed the sewage up a 100 ft. hill at approx. a 6 degree slope. The problem is that our slips are spread out without a consistent layout. What kind of pump system do you recommend?” John S. Seattle, WA

A: John, The best idea is to estimate the amount of traffic in the high season like July/August. The number of pump out units you will need depends on how many boats you intend to service at once. Many marinas with 100 slips or more typically have between two and eight pump out collection systems read more

Mud Sucker Diaphragm Pumps Available in Costa Rica

Wastecorp’s Mud Sucker diaphragm pumps are now available in Chile with distribution in Santiago, Iquique, Talcahuano and Villarrica. In cooperation with Zebol S.A., a Chilean pump distribution company with 20 years of experience, Wastecorp has been reaching the oil refinery market with emphasis on the Mud Sucker B Series.

Start a Small Business: Pumping Waste Oil, Vegetable Oil and Grease Trap Waste

Did you ever consider starting a food type grease or waste oil collection service? Did you ever wonder what kind of equipment you would need to start to become a “greaser”? The tough economy has enabled many creative local entrepreneurs to start their own business.

There are a few factors to consider when beginning this type of business: First, consider what kind of oil collection business you want to start – there is the mobile collection system where you collect the waste oil using a truck mounted pump out and temporary storage tank. You may also consider developing a treatment facility to transfer fats, oil and grease to offer customers the full service oil collection business.

Mobile Collection Systems

Many restaurants, car dealers, truck and car washes, paint factories and industrial facilities look to eliminate the headache of disposing of used oils. In many areas local bylaws

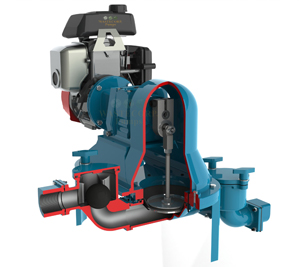

Trash Pump Video – Food Processing Facility

Wastecorp's self priming centrifugal pump line is a versatile series of trash pumps. You choose between 2" and 10" models capable of pumping up to 6300 GPM.