Drinking Water Transportation Systems

One of the questions we get from municipal emergency management agencies and larger corporations is if there is an economical method of providing clean drinking water via trailer or skid. Gilbert K from Clay County TN exemplifies some of the concerns about providing potable water in his community:

We have a rural community of about 20 residents where drinking water is not always accessible. A water truck service has been costing us a fortune to fill the residential drinking water tanks serving the homes. We are trying to reduce our budget by possibly investing in our own water trailer system but the unit has to be safe for storing and dispensing drinking water. We would be filling the water trailer either at the municipal water treatment plant 20 miles away or by a fire hydrant closer to the community. We also want to make sure that an F-150 truck can safely tow this trailer full. Please provide suggestions and a budgetary proposal. Thank you Gilbert – Clay County, TN USA.

Gilbert, you have a lot of options to provide your own municipal drinking water transportation system. We call it a water trailer or water wagon. We have supplied disaster relief agencies and emergency management government with the WT-500-DT for years – see the pictures in this post or click on the photo to see the website specs of the unit. This system feat

Primary Sludge Pumps at a WWTP

Primary sludge pumps are typically used in municipal Wastewater treatment facilities to transfer digested sewage and sludge. This is a broad pump category that encompasses positive displacement pumps to pump sludge in ranges usually up to about 500 GPM. The choices of pumps vary from double diaphragm pumps, plunger pumps, double disc pumps, rotary lobe pumps, progressive cavity pumps and more.

In todays pump marketplace, there are generally two schools that operators and consulting engineers follow when specifying primary sludge pumps. The first option is to install a more robust pump model with features like ball check technology to manage varying solids percentages or abrasive solids. These pumps typically cost a bit more to begin, but the spare parts costs are much lower down the road. Examples of such pumps are plunger pumps, double diaphragm pumps and double disc pumps.

New Diaphragm Pump Options for Malaysia

The Mud Sucker Diaphragm Pump is expanding its presence across Malaysia with a wide variety of our Global pump products available in Kuala Lumpur, Kuala Terengganu, Kota Bharu, Ipoh, Kerteh and Dungun. Our diaphragm pumps have made great headway replacing older technology air operated double diaphragm pumps (AODD pumps) across the country due to increased attention

How to Pump Cooking Oil from Restaurants

In this post we provide answers to the question of how to pump out used cooking oil from restaurant waste collection bins especially in colder weather? Used cooking oil transforms into a gel when the surrounding temperature dips below 40°F (4°C). This makes the fluid very difficult to pump. Roger F., from Charlotte, NC conveys the difficulty in pumping cooking oil:

“We are trying to find optimum pumping solution for pumping used cooking oil (uco) from 100- 300 gallon grease bins at restaurant accounts. We’ve recently opened a plant in the Charlotte area and have been pumping with a trash pump. It may have started off great but the trash pump failed after about six months as colder weather gelled the oil. We want a solution to

mount to our truck that will allow us to effectively pump when cooking oil becomes like a gel or slurry at colder temps.” Thanks Roger F. – Charlotte, NC USA

Roger’s concern is well documented for waste oil collectors especially in Northern climates. First, you might want to try thinnin

Connecticut Pump Options

Wastecorp has proudly served Connecticut's municipal and industrial pumping needs over over 20 years. From Darien, Derby, Hartford, Mystric and beyond our plunger pumps, diaphragm pumps trash pumps and now disc pumps work hard for the millions who indirectly depend on reliable pumping equipment to keep sewage in its place and water flowing.

Food Waste Pumps – Food Processing Facilities

The challenge for food waste processors is finding pumps for their applications that are versatile and robust enough to pump through a variety of conditions. This was just the case for a Fresno, California based

alternative energy company who earned a multi-year contract to accept expired and spoiled canned tomato paste, tomato sauce, fruit juice, ketchup and bulk tomatoes for Fresno and Bakersfield area grocery stores, prisons, hospitals, food preparation companies and more.

Wastecorp was contacted by a South New Jersey WWTP to provide upgraded sewage pumps to transfer wastewater,

Finding Diaphragm Pump Parts for Any Make

Older diaphragm pump parts can be difficult to find and repair kits or overhauls even trickier. However, a few steps can help you identify the components you need to get your pump up and running again. Replacement diaphragms are the easiest to match. We come across Mud Sucker, Home Lite, Mud Hog, AMT, Tsurumi, Multiquip, Wacker and Honda diaphragm pumps all the time that we can match. Repair kits like pump rods, covers, flapper valves and gaskets might be a bit tougher.

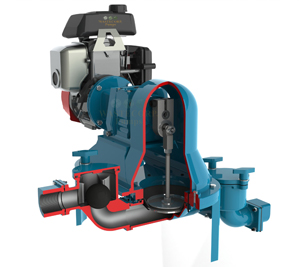

Diaphragm Pump Technology Advances

Diaphragm pump technology for wastewater pumping, waste oil, septic and food processing applications has advanced. Wastecorp, a designer and manufacturer of diaphragm pumps, has invested in R&D to build better diaphragm pumps. Wastecorp’s vision is to become the worldwide leader in diaphragm pump technology and reaching this goal is becoming closer for the company every year.

At the heart of the latest diaphragm pump technology update is “quick release yoke technology” The principle here is to make it easier for the operator of the pump to conduct routine maintenance. Quick release technology has been available up until this point on the Mud Sucker premium B Series professional line. This type of diaphragm pump uses ball valves or check ball technology to move wastewater. However, in 2020, the Mud Sucker FA Series diaphragm pump is also available with quick release technology.

The diaphragm flapper material is a severe duty rated elastomer for waste oil pumping and general wastewater pumping applications. You can also pump select corrosive fluids with this diaphragm pump but should check with the factory with your application first.

In the photo above, you see the new diaphragm pump, Mud Sucker model read more

Choices for Agricultural Wastewater Pumps

With agricultural wastewater pumping needs, both government and industry have the challenge of finding pumping equipment that can handle chemical based wastewater like insecticides and PH balancing solutions plus wastewater manure, hair and other solids.