Primary Sludge Pumps | What you Should Know

With tough sludge pumping applications like those found at municipal Wastewater Treatment Facilities, (WWTP’s) having the right primary sludge pumps can help reduce hassles and your spare parts budget down the road. This was just the case for the City of Meridian’s recent wastewater treatment facility upgrade and expansion in Meridian, Idaho.

The City of Meridian has utilized ball check technology for years to help move tough sewage and sludge. Ball check technology enabled pumps have moved trillions of gallons of raw sewage worldwide for over 50 years and is the back bone of Wastecorp’s plunger pump, profe

Honey Wagons: How to Set-Up and Use

Getting the most of your honey wagon pump out system will help you maximize your day-to-day productivity. In the video above you will see how to use the honey wagon to pump both into and out of the tank with the same pump. You will also see how easy it is to change the direction of flow when needed.

A New Direction in Plunger Pumps: Sludge Pumping Capabilities With A Cleaner Design

When consulting engineers’ and facility operators begin to plan an upgrade for their sewage treatment plants most are considering four primary pumps: Plunger pump technology, rotary lobe pumps, progressive cavity and double disc pumps.

How to Pump Out of Waste Pits

Waste pits, sump pits, catch basin, overflow pit, pumping from waste containers are all pump applications that medium and large size facilities have to contend with in the food, manufacturing, chemicals, and septic management industries. Having the right pump and piping arrangement can help you get the job done properly.

We want to walk you through just a few of the critical factors you need to consider when planning your waste pit application.

What is the Sump Pit Depth That You Need to Pump Out Of?

The depth of your pit or suction line will determine what type of pump you need. For pits from 5’-10’ deep a diaphragm pump may work well for this application. The photo yo

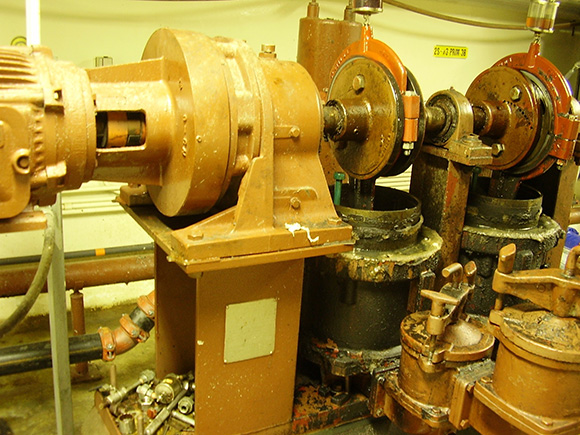

Pump Industry News: Replacing a Komline Sanderson Plunger Pump

Many of our wastewater treatment plant operators looking to upgrade their sewage pumps to the next generation plunger pumps have a wide set of options for a no piping change or little alternation to the existing set up. New sewage pumps can help make the facility more efficient and productive. This is available to all plunger pump customers including competing makes like Komline Sanderson* and Carter* Plunger Pump customers.

With a 3 hp motor, and 4″ discharge. Mike D. from Fort Worth Texas illustrates a number of pump questions we get from public utilities operators.

“I am looking to replace 2 Komline Sanderson KS-9 plunger pumps at my wastewater treatment facility. The pump characteristics are 140 GPM at 90 ft head. We get some grit in our sewage and we have a grinder on the suction lines of both pumps. Current pump is duplex plunger pump general arrangement. What is your equivalent of this pump? Do I have to make piping changes to my effluent lines? And what other pumps do you manufacture that we could consider installing? .” Thanks, Mike D. Fort Worth, Texas

Well Mike, you have a few different options when replacing those Komline Sanderson Plunger Pumps. As you know all plunger pumps are positive displacement pumps so you will have pulsation in your lines. Our air chambers which act as pulsation dampeners are on both the suction and the discharge which really helps with thinner

Updating Your Wastewater Pumping System

When it comes time to update your wastewater pump system especially for mobile applications you should know your options. There are a range of products available with components designed for your specific application. The photo you see left was sent by a multinational mining company who contacted Wastecorp to design a new fleet system to collect used machine oil and wastewater from various mining sites. The previous pump systems had been in service for over 30 years and the customer required an updated pump out system with added durability and pumping power. The customer also had height restrictions for pumping in a variety of mining facilities including shafts and waste ponds.

Wastecorp went to work and supplied the customer with quantity 10 read more

How to Change The Disc Assembly on A Double Disc Pump

The video below shows how to change the trunnion on a Sludge Pro double disc pump. As you can see most of the maintenance is done with the operator standing up and most components visible to the operator.

Safety First

Changing the disc assembly on a Sludge Pro double disc pump is a simple process which can usually be done within 30 minutes-45 minutes.

Airport Stormwater Pump Options

At airports around the world, storm water gets mixed with jet fuel during storms and must be properly pumped and treated before returning into the waterways. Most airports have stormwater pumping stations to prevent flood damage, protect the water supply and capture runoff before returning to canals levee’s

Resolving Sewage Pump Problems at Smaller WWTP’s

How to resolve sewage pumping problems at smaller WWTP’s is a question on the minds of thousands of operators worldwide. These facilities pump municipal sewage, storm water, melting snow, road grit and so much more for smaller communities. While the gallons per day pumped may not be as high as urban sewage treatment plants, the need for reliable sludge pumps is just as great.

Wastecorp was contacted by a South New Jersey WWTP to provide upgraded sewage pumps to transfer wastewater, sludge and s

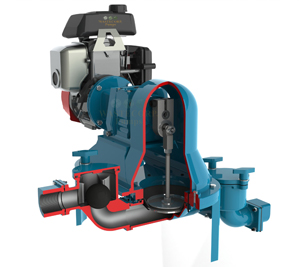

Diaphragm Pump Technology Advances

At the heart of the latest diaphragm pump technology update is “quick release yoke technology” The principle here is to make it easier for the operator of the pump to conduct routine maintenance. Quick release technology has been available up until this point on the Mud Sucker premium B Series professional line. This type of diaphragm pump uses ball valves or check ball technology to move wastewater. However, in 2020, the Mud Sucker FA Series diaphragm pump is also available with quick release technology.

The diaphragm flapper material is a severe duty rated elastomer for waste oil pumping and general wastewater pumping applications. You can also pump select corrosive fluids with this diaphragm pump but should check with the factory with your application first.

In the photo above, you see the new diaphragm pump, Mud Sucker model read more