WWTP Expands in New York Led by Arcadis Engineers, Kiewit Contractors, Siewert Equipment, Jett Industries and Wastecorp Pumps

New Wastewater Treatment Upgrades

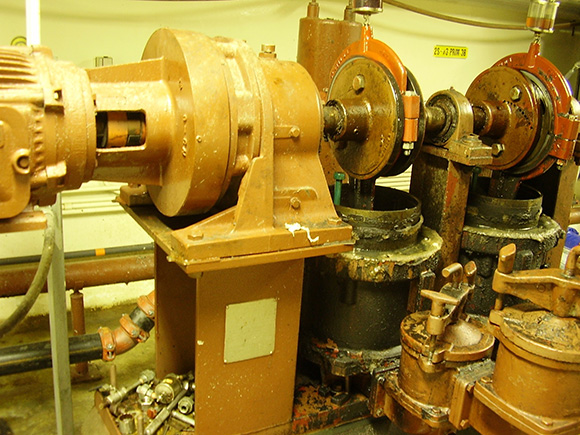

An upgraded Wastewater Treatment Plant in New York State is well on its way to becoming an advanced wastewater pumping and treatment center for a rapidly developing area. Among the changes include new [...]

Upstate New York Municipal WWTP Upgrades Sewage Pump

Winter in northern climates brings a host of challenges for municipal sewage pumping. With heavy rain and snowfall, America sewage treatment plants must pump through a cycle of runoff and grit in addition [...]

Advancements in Sewage Pump Technology

Plunger Pump Sewage Transfer Pump in PA

For wastewater treatment facilities that are upgrading their sewage pumping equipment, getting the right pump technology to do the job is critical. For one thing,

Pump Industry News: Replacing a Komline Sanderson Plunger Pump

Many of our wastewater treatment plant operators looking to upgrade their sewage pumps to the next generation plunger pumps have a wide set of options for a no piping change or little alternation to the existing set up. New sewage pumps can help make the facility more efficient and productive. This is available to all plunger pump customers including competing makes like Komline Sanderson* and Carter* Plunger Pump customers.

With a 3 hp motor, and 4″ discharge. Mike D. from Fort Worth Texas illustrates a number of pump questions we get from public utilities operators.

“I am looking to replace 2 Komline Sanderson KS-9 plunger pumps at my wastewater treatment facility. The pump characteristics are 140 GPM at 90 ft head. We get some grit in our sewage and we have a grinder on the suction lines of both pumps. Current pump is duplex plunger pump general arrangement. What is your equivalent of this pump? Do I have to make piping changes to my effluent lines? And what other pumps do you manufacture that we could consider installing? .” Thanks, Mike D. Fort Worth, Texas

Well Mike, you have a few different options when replacing those Komline Sanderson Plunger Pumps. As you know all plunger pumps are positive displacement pumps so you will have pulsation in your lines. Our air chambers which act as pulsation dampeners are on both the suction and the discharge which really helps with thinner

Sludge Handling Equipment Improvement Project – Municipal

When Wastecorp works with consulting engineers and operators on sewage treatment plant improvements, we look to limiting the footprint inside the plant due to the

Double Disc Pump Comparison Guide for Engineers, Operators and Pump Distributors

Wastecorp has published a double disc pump comparison guide for consulting engineers, end users and pump distributors. This resource explains the difference between two different pump types and the methods each use to pump sewage, sludge and wastewater. You can download this comparison guide by clicking here or continuing to read below.

Who is Wastecorp?

Wastecorp Pumps is an ISO 9001 and ISO 14001 certified pump manufacturer. Wastecorp manufactures the Sludge Pro brand double disc pump. The company specializes in sewage pump and wastewater pump manufacturing. This includes multiple products for municipal/industrial applications. Wastecorp has manufactured pumps since 1993 in the United States and Canada. Information about Sludge Pro Double Disc Pumps can be found at

https://wastecorp.com/Products/Disc-Pumps

What is a Penn Valley Pump (PVP)?

The Penn Valley pump is a diaphragm pump. PVP has fully acknowledged this in their patent # US 7,559,753 B2. The patent references George Burrage’s (a family member of PVP President) patent application # GB 2013287A as the basis of construction for the PVP pump. Nowhere in GB 2013287A does it reference a disc at all. This legal document fully acknowledges the fact that the Penn Valley pump is a diaphragm pump. PVP also references the use of diaphragms in all of their trademark registrations.

What is The Difference Between Penn Valley (PVP) and Sludge Pro Pumps?

Sludge Pro double disc pumps are available with either a clack valve or a ball valve configuration. The operator selects one or the other. As of 2017, Penn Val