Pumping sewage for a city of over eight million people can be a challenging task and that’s exactly what the City of New York and surrounding communities like Westchester County must contend with.

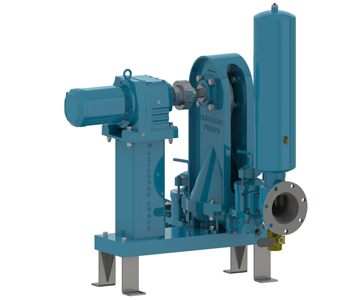

Sludge Pumping in New York With Sludge Master Plunger Pumps

Landfill Leachate Pumps

Pumping landfill leachate, wastewater containing solids and other debris is a challenging task that requires high performance pump systems to hold up to day-to-day heavy duty pumping tasks. There are added variables like solids, methane gas and potential site risks that must be taken into account when planning for a landfill wastewater and leachate pumping system.

read moreThe Problem of Space Constraints at Wastewater Treatment Plants

a Memphis, Tennessee area sewage treatment plant which recently installed a Space Saver after trying double disc and progressive cavity pumps

What Kind of Dry Prime Pump Should We Use at our Water Treatment Facility

We get a lot of questions from WWTP’s and public works departments asking about the differences between regular trash pumps on a trailer with diesel engines and dry prime pumps. The following question from a municipal pump operator exemplifies the discussion:

Hi, we use your double disc pumps at our primary scum pumping operation but we also have a need for a dry prime pump or a regular trash pump for pumping out our digesters for

The Agony of Lobe Pumps and Their Alternatives

The first visit to a wastewater treatment plant with lobe pumps was a shocker. $550,000 in replacement parts costs spent over the course of just 3-4 years. My response to the plant operator was, “you haven’t spent $550,000 in plunger pump parts over 30 years” so why is the consulting engineer specifying those types of pumps!”

Questions: How to Plan a Pump Out for a Larger Marina

I need to outfit our 200 slip marina with new pump stations with one larger pump to feed the sewage up a 100 ft. hill at approx. a 6 degree slope. The problem is that our slips are spread out without a consistent layout. What kind of pump system do you recommend?

Exploring Diaphragm Pump Components: A Guide to Chemical Compatibility

Diaphragm pumps have become critical to many industries thanks to their versatility and durability. For a diaphragm pump to perform optimally, however, care must be taken during the materials of construction [...]

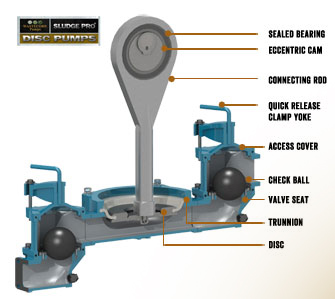

read moreDouble Disc Pumps and Municipal Sewage Pumping

For years, we have been asking wastewater treatment plants (WWTP) what they like about double disc pumps and what they don’t like. We have even been compiling a database with what regions of the USA and Canada have success with this type of pump for sewage and which areas have had more challenges.

One of the things that most WWTP’s say is that there has been limited competition in the specifications put out for bid by municipalities and consulting engineers working on wastewater projects. As we all know a monopoly in the pump industry is seldom a good thing for quality, innovation and of course pricing for pumps and parts.

The Dynamic Role of Diaphragm Pumps in the Food & Beverage Industry

Modern food production demands safety and efficiency in all of its processes. During every step of production, preventing contamination and waste is crucial to delivering a product that maintains consumer [...]

read moreMobile Drinking Water Stations

Street festival mobile fresh water source. Can be moved to various areas of the event.

Mobile drinking water stations are designed for both government and private

read more