Why Mudsucker Diaphragm Pumps Are Ideal for Wastewater Treatment

In a world of increasing water scarcity, wastewater management has become crucial to limiting the adverse effects of climate change and population growth. Purifying wastewater allows us to conserve [...]

Pumping Out Tanks With Diaphragm Pumps

You name the tank that needs to be pumped out and we have heard of at least a few customer applications that correspond with that tank. Underground septic tanks, lagoon transfer, transport truck tankers, locomotive tankers, waste pits and waste vegetable oil drums are among the most popular.

Wastecorp Mud Sucker Pumps Available With Variable Frequency Drives (VFD’S)

Do you need to adjust the speed of your pump’s electric motor, modulating the power being delivered? We’ve got good news; all Mud Sucker diaphragm pump models are now available with a variable frequency drive (VFD).

-

- VFD’s

help to accommodate fluctuating demand by adjusting pump energy consumption and costs by adjusting the amount of power delivered to the motor for pumping specific tasks.

Public utilities and industrial fluid handling facilities are increasingly specifying pumps with VFD’s to reduce maintenance costs and energy consumption. Since not all pumping jobs are alike, the pump adjusts the power being delivered when handling higher than normal levels of slurry, mud, raw sewage, water and more.

New Condensate Pumps for NYC WWTP

This was just the case for Coney Island’s condensate vacuum pump operations located less than one hundred feet from an inland waterway that flows into the Atlantic Ocean. Salt water destroyed the existing Mud Hog diaphragm pumps, valve systems and electrical panels causing tens of thousands of dollars worth of damage.

Dredging Pump Projects Made Easier

With dredging applications, Wastecorp generally encounters at least a few different kinds of projects: city or town sanctioned projects that are part of waterway management programs and private projects that include beautification, enhanced recreational access and improved appearance. For public projects, we generally work with engineering

Waste Containment Pump Systems | Your Options

Personal waste containment systems or “honey wagons” as they are sometimes called in the pump industry have come along way in just the last few years. In response to the soaring costs of vac truck services, everyone from those needing septic pumping, waste oil pumping and used vegetable oil transfer have found an economical alternative in owning a personal waste containment systems.

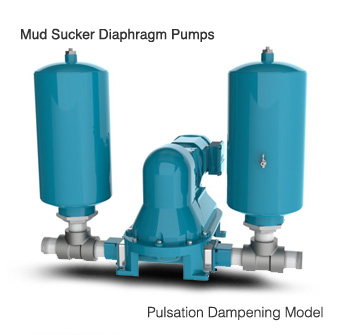

Pumps: How to Maintain a Continuous Flow and Minimize Pulsation

With pumping applications, one of the challenges you face especially when pumping thinner liquids, is to maintain continuous flow without “jerking the hose” or disruptions in pump productivity. One of the consulting engineering firms we have worked with in California illustrates this point well:

Primary Sludge Pumps at a WWTP

Primary sludge pumps are typically used in municipal Wastewater treatment facilities to transfer digested sewage and sludge. This is a broad pump category that encompasses positive displacement pumps to pump sludge in ranges usually up to about 500 GPM. The choices of pumps vary from double diaphragm pumps, plunger pumps, double disc pumps, rotary lobe pumps, progressive cavity pumps and more.

In todays pump marketplace, there are generally two schools that operators and consulting engineers follow when specifying primary sludge pumps. The first option is to install a more robust pump model with features like ball check technology to manage varying solids percentages or abrasive solids. These pumps typically cost a bit more to begin, but the spare parts costs are much lower down the road. Examples of such pumps are plunger pumps, double diaphragm pumps and double disc pumps.

How to Pump Cooking Oil from Restaurants

In this post we provide answers to the question of how to pump out used cooking oil from restaurant waste collection bins especially in colder weather? Used cooking oil transforms into a gel when the surrounding temperature dips below 40°F (4°C). This makes the fluid very difficult to pump. Roger F., from Charlotte, NC conveys the difficulty in pumping cooking oil:

“We are trying to find optimum pumping solution for pumping used cooking oil (uco) from 100- 300 gallon grease bins at restaurant accounts. We’ve recently opened a plant in the Charlotte area and have been pumping with a trash pump. It may have started off great but the trash pump failed after about six months as colder weather gelled the oil. We want a solution to

mount to our truck that will allow us to effectively pump when cooking oil becomes like a gel or slurry at colder temps.” Thanks Roger F. – Charlotte, NC USA

Roger’s concern is well documented for waste oil collectors especially in Northern climates. First, you might want to try thinning the l

Diaphragm Pumps Now Available With Control Panels

One of the trending customer requests this past year is custom diaphragm pump stations equipped with control panels and mobility options. To give you an example (and some ideas for your own pump application), one of our customers who happens to be one of the largest snack food producers globally, contacted Wastecorp’s engineering department asking for design proposals for a 3″ diaphragm pump out system complete with a mobility kit and the ability to directly control the pump operation. The diaphragm pump unit needed to be manufactured to maneuver easily on the factory floor aisles with custom dimensions. The pumps travel throughout the facility transferring chocolate based waste slurry and vegetable oil residues.

Look to the left and this is what our pump engineers came up with. This is the 3FA-EC diaphragm pump control panel model with e-stop, push bottom start and a specialized float system which detects when the pump should begin operating and automatically turn off. The customer ended up ordering 10 units for other facilities. The best part of this case study is that Wastecorp and our customer are in constant contact reviewing the benefits of the pump system and making design changes for future facility needs. We work one-on-one for custom results and constant improvement.

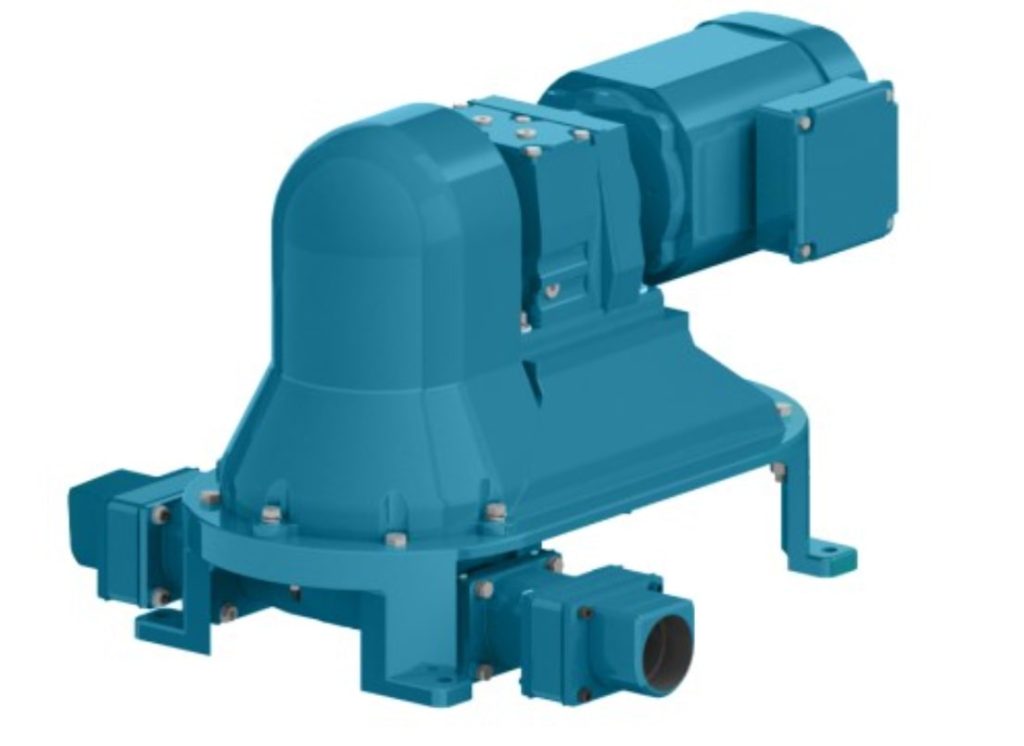

The Mud Sucker diaphragm pump with transformer you see here is designed with a more compact installation in mind. The customer ordered this Mud Sucker 3″ diaphragm pump for assembly line food processing waste transfer tasks. This unit transfers waste pit slurries and detects when the pit is empty or in need of pumping. The pump is also