Pumping Out Tanks With Diaphragm Pumps

You name the tank that needs to be pumped out and we have heard of at least a few customer applications that correspond with that tank. Underground septic tanks, lagoon transfer, transport truck tankers, locomotive tankers, waste pits and waste vegetable oil drums are among the most popular.

Primary Sludge Pumps | What you Should Know

With tough sludge pumping applications like those found at municipal Wastewater Treatment Facilities, (WWTP’s) having the right primary sludge pumps can help reduce hassles and your spare parts budget down the road. This was just the case for the City of Meridian’s recent wastewater treatment facility upgrade and expansion in Meridian, Idaho.

The City of Meridian has utilized ball check technology for years to help move tough sewage and sludge. Ball check technology enabled pumps have moved trillions of gallons of raw sewage worldwide for over 50 years and is the back bone of Wastecorp’s plunger pump, profe

Upstate New York Municipal WWTP Upgrades Sewage Pump

Winter in northern climates brings a host of challenges for municipal sewage pumping. With heavy rain and snowfall, America sewage treatment plants must pump through a cycle of runoff and grit in addition [...]

Planning for New Digester Pumps

Climate changes in the Northeast has also played a role in nudging local government to invest in sewage treatment pumping equipment as unpredictable storms can overload the system.

Sludge Pumping in New York With Sludge Master Plunger Pumps

Pumping sewage for a city of over eight million people can be a challenging task and that’s exactly what the City of New York and surrounding communities like Westchester County must contend with. Wastecorp completed a plunger pump sludge moving project for the Ossining Waste Water Treatment Plant; a facility located about 30 miles from Manhattan and within walking distance to Sing Sing Correctional facility. Wastecorp’s plunger pumps were approved by GHD Consulting Engineers. Mace Contracting completed the installation. See video

Ossining replaced two existing plunger pumps with next generation Wastecorp Plunger Pumps HPE Series -triplex model HPE 1142. The pumps are designed to transfer thickened sludge to loading trucks that haul it away for sanitary treatment. The pumps feature heavy duty 11” plungers with a guided stuffing box system to reduce wear on the packing, plungers and connecting rods read more about the guided stuffing box system.

Part of Wastecorp’s onsite activities included our extensive classroom training program for facility maintenance staff. Plunger pump training helps staff to optimize performance of the pumping equipment and makes regular maintenance easier, quicker and safer. During the presentation staff learned how to service major components of the pumps including replacing t

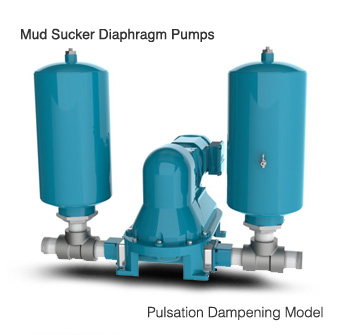

Pumps: How to Maintain a Continuous Flow and Minimize Pulsation

With pumping applications, one of the challenges you face especially when pumping thinner liquids, is to maintain continuous flow without “jerking the hose” or disruptions in pump productivity. One of the consulting engineering firms we have worked with in California illustrates this point well:

Diaphragm Pumps Now Available With Control Panels

One of the trending customer requests this past year is custom diaphragm pump stations equipped with control panels and mobility options. To give you an example (and some ideas for your own pump application), one of our customers who happens to be one of the largest snack food producers globally, contacted Wastecorp’s engineering department asking for design proposals for a 3″ diaphragm pump out system complete with a mobility kit and the ability to directly control the pump operation. The diaphragm pump unit needed to be manufactured to maneuver easily on the factory floor aisles with custom dimensions. The pumps travel throughout the facility transferring chocolate based waste slurry and vegetable oil residues.

Look to the left and this is what our pump engineers came up with. This is the 3FA-EC diaphragm pump control panel model with e-stop, push bottom start and a specialized float system which detects when the pump should begin operating and automatically turn off. The customer ended up ordering 10 units for other facilities. The best part of this case study is that Wastecorp and our customer are in constant contact reviewing the benefits of the pump system and making design changes for future facility needs. We work one-on-one for custom results and constant improvement.

The Mud Sucker diaphragm pump with transformer you see here is designed with a more compact installation in mind. The customer ordered this Mud Sucker 3″ diaphragm pump for assembly line food processing waste transfer tasks. This unit transfers waste pit slurries and detects when the pit is empty or in need of pumping. The pump is also

Choices for Agricultural Wastewater Pumps

With agricultural wastewater pumping needs, both government and industry have the challenge of finding pumping equipment that can handle chemical based wastewater like insecticides and PH balancing solutions plus wastewater manure, hair and other solids.

Mobile Pumping Solutions

With the official start of camping and boating season right at our door many campgrounds and marinas are considering their septic pumping services for the new season. A common problem at small to mid size campgrounds and marinas is that septic tank trucks have a difficult time maneuvering in tight spaces and of course, there is always the cost and scheduling issues.

Honey Wagon Manufacturer

One solution to this problem is the new 100 gallon Wastecorp Mud Sucker honey wagon. The MS-100 can connect to most utility vehicles or ATV’s for easy transportation to trailers, RV’s and even boats. But the best feature of this pumping system is that the three way valve system allows you to use the pump to both pump waste in and out of the tank. You don’t have to mess with the discharge valve (although the MS-100 has one as a back-up) you simply turn the valve and pump out to an approved dump station. This package also includes everything you need including the high grade crush

A New Pump Out Caddy for Multiple Uses

One of the things about our honey wagon pump out systems that continues to amaze us is just how many applications our customers use them for. While originally designed for marinas, RV pump outs and locomotive holding tank pump outs