Primary Sludge Pumps | What you Should Know

With tough sludge pumping applications like those found at municipal Wastewater Treatment Facilities, (WWTP’s) having the right primary sludge pumps can help reduce hassles and your spare parts budget down the road. This was just the case for the City of Meridian’s recent wastewater treatment facility upgrade and expansion in Meridian, Idaho.

The City of Meridian has utilized ball check technology for years to help move tough sewage and sludge. Ball check technology enabled pumps have moved trillions of gallons of raw sewage worldwide for over 50 years and is the back bone of Wastecorp’s plunger pump, profe

Upstate New York Municipal WWTP Upgrades Sewage Pump

Winter in northern climates brings a host of challenges for municipal sewage pumping. With heavy rain and snowfall, America sewage treatment plants must pump through a cycle of runoff and grit in addition [...]

A New Direction in Plunger Pumps: Sludge Pumping Capabilities With A Cleaner Design

When consulting engineers’ and facility operators begin to plan an upgrade for their sewage treatment plants most are considering four primary pumps: Plunger pump technology, rotary lobe pumps, progressive cavity and double disc pumps.

How to Pump Wet Wipes and Cooking Oil

In North America, municipal wastewater treatment operators routinely voice their concerns to Wastecorp about the use of wet pipes by the general public and then flushing them down the toilet. “Do you guys make a pump that can better handle the wet wipes” is a question Wastecorp frequently receives at our sludge pump call centers. Jim K. from Winston Salem North Carolina tells it like it is:

Sludge Pumping in New York With Sludge Master Plunger Pumps

Pumping sewage for a city of over eight million people can be a challenging task and that’s exactly what the City of New York and surrounding communities like Westchester County must contend with. Wastecorp completed a plunger pump sludge moving project for the Ossining Waste Water Treatment Plant; a facility located about 30 miles from Manhattan and within walking distance to Sing Sing Correctional facility. Wastecorp’s plunger pumps were approved by GHD Consulting Engineers. Mace Contracting completed the installation. See video

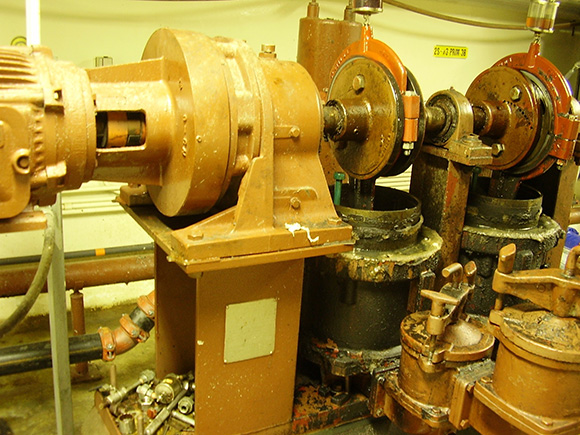

Ossining replaced two existing plunger pumps with next generation Wastecorp Plunger Pumps HPE Series -triplex model HPE 1142. The pumps are designed to transfer thickened sludge to loading trucks that haul it away for sanitary treatment. The pumps feature heavy duty 11” plungers with a guided stuffing box system to reduce wear on the packing, plungers and connecting rods read more about the guided stuffing box system.

Part of Wastecorp’s onsite activities included our extensive classroom training program for facility maintenance staff. Plunger pump training helps staff to optimize performance of the pumping equipment and makes regular maintenance easier, quicker and safer. During the presentation staff learned how to service major components of the pumps including replacing t

The Problem of Space Constraints at Wastewater Treatment Plants

a Memphis, Tennessee area sewage treatment plant which recently installed a Space Saver after trying double disc and progressive cavity pumps

Pumping Wastewater in Nassau County

Pumping wastewater in Nassau County NY poses unique challenges. First the county borders Long Island Sound to the North and the Atlantic ocean to the south which can bring variations in both weather and the types of wastewater that need to be pumped. Nassau County is home to over 1.3 million residents with a mix of suburban residents and vacation properties.

The City of Long Beach, New York was impacted by Hurricane Sandy several years ago. The municipal wastewater treatment plant experienced flooding and equipment damage. An additional challenge is a nearby recreation center that includes a golf center. With golf balls and other debris entering the sewage system, the pumps were requested to manage unexpected solids. Wastecorp was awarded the bid to replace an existing plunger pump to upgrade the existing infrastructure. Since the facility is so close to the ocean, a grinder was also installed to manage storm surge debris that will likely occur in the future.

Wastecorp worked with local Long island public works contractor Phillip Ross Industries to design, manufacture and install a read more

Plunger Pump Sewage Transfer Pump in PA

For wastewater treatment facilities that are upgrading their sewage pumping equipment, getting the right pump technology to do the job is critical. For one thing,

Pump Industry News: Replacing a Komline Sanderson Plunger Pump

Many of our wastewater treatment plant operators looking to upgrade their sewage pumps to the next generation plunger pumps have a wide set of options for a no piping change or little alternation to the existing set up. New sewage pumps can help make the facility more efficient and productive. This is available to all plunger pump customers including competing makes like Komline Sanderson* and Carter* Plunger Pump customers.

With a 3 hp motor, and 4″ discharge. Mike D. from Fort Worth Texas illustrates a number of pump questions we get from public utilities operators.

“I am looking to replace 2 Komline Sanderson KS-9 plunger pumps at my wastewater treatment facility. The pump characteristics are 140 GPM at 90 ft head. We get some grit in our sewage and we have a grinder on the suction lines of both pumps. Current pump is duplex plunger pump general arrangement. What is your equivalent of this pump? Do I have to make piping changes to my effluent lines? And what other pumps do you manufacture that we could consider installing? .” Thanks, Mike D. Fort Worth, Texas

Well Mike, you have a few different options when replacing those Komline Sanderson Plunger Pumps. As you know all plunger pumps are positive displacement pumps so you will have pulsation in your lines. Our air chambers which act as pulsation dampeners are on both the suction and the discharge which really helps with thinner

Primary Sludge Pumps at a WWTP

Primary sludge pumps are typically used in municipal Wastewater treatment facilities to transfer digested sewage and sludge. This is a broad pump category that encompasses positive displacement pumps to pump sludge in ranges usually up to about 500 GPM. The choices of pumps vary from double diaphragm pumps, plunger pumps, double disc pumps, rotary lobe pumps, progressive cavity pumps and more.

In todays pump marketplace, there are generally two schools that operators and consulting engineers follow when specifying primary sludge pumps. The first option is to install a more robust pump model with features like ball check technology to manage varying solids percentages or abrasive solids. These pumps typically cost a bit more to begin, but the spare parts costs are much lower down the road. Examples of such pumps are plunger pumps, double diaphragm pumps and double disc pumps.