Upstate New York Municipal WWTP Upgrades Sewage Pump

Winter in northern climates brings a host of challenges for municipal sewage pumping. With heavy rain and snowfall, America sewage treatment plants must pump through a cycle of runoff and grit in addition [...]

Double Disc Pumps and Municipal Sewage Pumping

For years, we have been asking wastewater treatment plants (WWTP) what they like about double disc pumps and what they don’t like. We have even been compiling a database with what regions of the USA and Canada have success with this type of pump for sewage and which areas have had more challenges.

Food Waste to Energy Pumps: What You Should Know

Our client is currently using progressive cavity pumps in a food waste to energy application. The problem is the seafood shells and other abrasive matter are destroying the rotors and costing the facility a fortune in repair costs. They are fed up and want another alternative. You were referred to us by another client who has used your plunger pumps with success for this application and suggested I call you.

How to Pump Out of Waste Pits

Waste pits, sump pits, catch basin, overflow pit, pumping from waste containers are all pump applications that medium and large size facilities have to contend with in the food, manufacturing, chemicals, and septic management industries. Having the right pump and piping arrangement can help you get the job done properly.

We want to walk you through just a few of the critical factors you need to consider when planning your waste pit application.

What is the Sump Pit Depth That You Need to Pump Out Of?

The depth of your pit or suction line will determine what type of pump you need. For pits from 5’-10’ deep a diaphragm pump may work well for this application. The photo yo

Pumping Wastewater in Nassau County

Pumping wastewater in Nassau County NY poses unique challenges. First the county borders Long Island Sound to the North and the Atlantic ocean to the south which can bring variations in both weather and the types of wastewater that need to be pumped. Nassau County is home to over 1.3 million residents with a mix of suburban residents and vacation properties.

The City of Long Beach, New York was impacted by Hurricane Sandy several years ago. The municipal wastewater treatment plant experienced flooding and equipment damage. An additional challenge is a nearby recreation center that includes a golf center. With golf balls and other debris entering the sewage system, the pumps were requested to manage unexpected solids. Wastecorp was awarded the bid to replace an existing plunger pump to upgrade the existing infrastructure. Since the facility is so close to the ocean, a grinder was also installed to manage storm surge debris that will likely occur in the future.

Wastecorp worked with local Long island public works contractor Phillip Ross Industries to design, manufacture and install a read more

Waste Oil and Wastewater Pumps for the Natural Gas Industry

Honey wagon waste containment systems are used across a wide range of industries and have endless application uses. Waste containment systems are used to pump out wastewater, oil or septic waste from storage tanks, lagoons, barrels and more. The national gas industry requires honey wagons as well. From natural gas well process uses, wastewater containment and facilities management, portable waste containment systems play a valuable role in collecting wastewater and safely transporting is to an environmentally responsible dump station. With the advent of fracking, our customer base for waste containment systems in New York State, PA, Virginia and Kentucky has rapidly expanded. Dustin R, from Lexington, KY recently contacted Wastecorp about a new pump out system for his Natural gas company:

“We are looking for a mobile tank system to drain used oil tanks. The pump we would like to use is an air driven diaphra

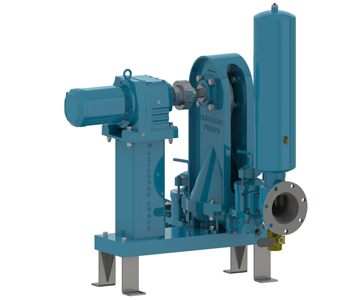

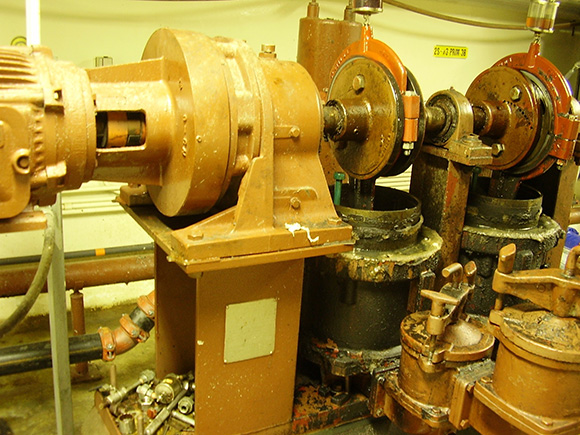

Pump Industry News: Replacing a Komline Sanderson Plunger Pump

Many of our wastewater treatment plant operators looking to upgrade their sewage pumps to the next generation plunger pumps have a wide set of options for a no piping change or little alternation to the existing set up. New sewage pumps can help make the facility more efficient and productive. This is available to all plunger pump customers including competing makes like Komline Sanderson* and Carter* Plunger Pump customers.

With a 3 hp motor, and 4″ discharge. Mike D. from Fort Worth Texas illustrates a number of pump questions we get from public utilities operators.

“I am looking to replace 2 Komline Sanderson KS-9 plunger pumps at my wastewater treatment facility. The pump characteristics are 140 GPM at 90 ft head. We get some grit in our sewage and we have a grinder on the suction lines of both pumps. Current pump is duplex plunger pump general arrangement. What is your equivalent of this pump? Do I have to make piping changes to my effluent lines? And what other pumps do you manufacture that we could consider installing? .” Thanks, Mike D. Fort Worth, Texas

Well Mike, you have a few different options when replacing those Komline Sanderson Plunger Pumps. As you know all plunger pumps are positive displacement pumps so you will have pulsation in your lines. Our air chambers which act as pulsation dampeners are on both the suction and the discharge which really helps with thinner

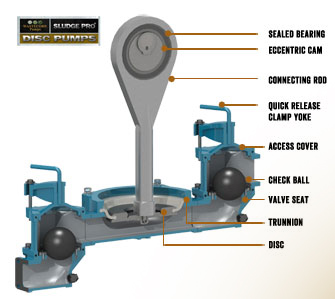

How a Double Disc Pump Works

We have all seen the outside of a double disc pump but rarely do we see what makes the pump actually work. Just to review, a double disc pump is a positive displacement pump that uses a trunnion (elastomer), a disc and a connecting rod to force sewage from the suction side to the discharge side of the pump by creating a vacuum inside the pump body. The valve chambers with the black check valves you see in the photo help to manage higher than normal concentrations of grit and solids in municipal wastewater.

Orange County Waste Acceptance Facility Looks for Pump Solutions

Orange county is home to dozens of resorts, hotels and theme parks which generate tens of millions of gallons of wastewater that needs to be treated every year. When an Orlando, Florida renewable energy company earned a multiyear contract to accept waste from local resorts and theme parks, they needed severe duty pumps to transfer thick slurries and solids.

The details of the project called on the requirement of pumps to transfer ground up seafood shells, grease trap waste, utensils, animal renderings, wastewater and more. In this application, the waste is unloaded from a tanker into a waste pit. The waste is then transferred to a conveyor system which then separates most of the foreign objects like utensils, large solids, plastic bags and more. The remaining waste is sent through the Sludge Master plunger pump and then to the digesters of the wastewater treatment plant. With millions of people visiting Orlando resorts and theme parks every year, this amounts to a lot of waste, as tanker trucks deliver new loads of slurry like liquid waste around the clock.

Working with Wastecorp, the company decided on a Sludge Master PE 942 with a 20 hp motor and mechanical force feed oiler for aut

Primary Sludge Pumps at a WWTP

Primary sludge pumps are typically used in municipal Wastewater treatment facilities to transfer digested sewage and sludge. This is a broad pump category that encompasses positive displacement pumps to pump sludge in ranges usually up to about 500 GPM. The choices of pumps vary from double diaphragm pumps, plunger pumps, double disc pumps, rotary lobe pumps, progressive cavity pumps and more.

In todays pump marketplace, there are generally two schools that operators and consulting engineers follow when specifying primary sludge pumps. The first option is to install a more robust pump model with features like ball check technology to manage varying solids percentages or abrasive solids. These pumps typically cost a bit more to begin, but the spare parts costs are much lower down the road. Examples of such pumps are plunger pumps, double diaphragm pumps and double disc pumps.