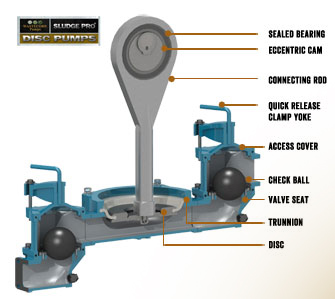

We have all seen the outside of a double disc pump but rarely do we see what makes the pump actually work. Just to review, a double disc pump is a positive displacement pump that uses a trunnion (elastomer), a disc and a connecting rod to force sewage from the suction side to the discharge side of the pump by creating a vacuum inside the pump body. The valve chambers with the black check valves you see in the photo help to manage higher than normal concentrations of grit and solids in municipal wastewater.

How a Double Disc Pump Works

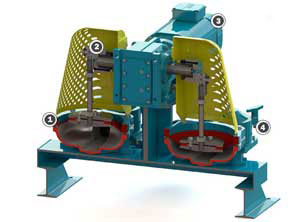

Pumps: How to Maintain a Continuous Flow and Minimize Pulsation

With pumping applications, one of the challenges you face especially when pumping thinner liquids, is to maintain continuous flow without “jerking the hose” or disruptions in pump productivity. One of the consulting engineering firms we have worked with in California illustrates this point well:

Sewage Handling Lift Stations

Our latest Wastecorp trash pump sewage lift stations have hit the market with two to four unit pump models available. Whether you need to replace your above ground, below ground, pre-engineered or auto-start pump stations there are a number of options available to you. For example, all pre-engineered sewage lift stations can accommodate up to 10" trash pumps capable of pumping up to 3500 GPM.

How to Plan a Marine Pump Out Station

Planning a marine pump out station is essential to getting the appropriate pump out equipment for your marina. Consulting other marinas in your area or a marine pump manufacturer ahead of when you actually need the system installed is your best bet. Wastecorp has generally found that marinas seem to be getting larger boat and yacht traffic in the last few years that need to be pumped out.

Double Disc Pump Comparison Guide for Engineers, Operators and Pump Distributors

Wastecorp has published a double disc pump comparison guide for consulting engineers, end users and pump distributors. This resource explains the difference between two different pump types and the methods each use to pump sewage, sludge and wastewater. You can download this comparison guide by clicking here or continuing to read below.

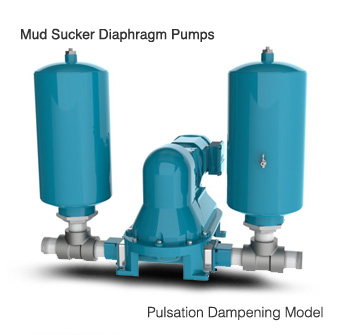

Diaphragm Pump Design and Engineering

Wastecorp didn’t invent the diaphragm pump but when we introduced the Mud Sucker diaphragm pump product line almost 17 years ago we set out to innovate and radically transform how customers transfer fluids.

HOA Pump Options for Wastewater Pumping

We are pumping mud and sediment from the bottom of our irrigation holding tanks from which we pump irrigation water collected from ditches in our community. We reuse this water to irrigate common areas and private lots

What’s New in Diaphragm Pumps?

Diaphragm pumps have had quite the evolution over the last few years with new innovations in diaphragm materials, pump body engineering, drive systems and overall design. This evolution is mainly end user driven; more facilities face budget constraints and have thus demanded cost effective solutions for transferring wastewater and slurry (which diaphragm pumps have traditionally offered). Diaphragm pump manufacturers have responded by offering heavy duty pump models that transcend their usual application capabilities and now may be suitable for areas that submersible pumps and trash pumps once dominated. Here’s a partial answer to how this evolution has happened: