State-of-the art food processing facilities and the engineers who design them have a challenge in finding the right pumps and control panels to transfer process wastewater. This was the case for fast food restaurant chain White Castle’s brand new innovative processing center in Vandalia, Ohio USA. Wastecorp worked with White Castle, local contractor PAE and Associates (who specialize in Wastewater treatment plant construction) and

Oil Water Separator Pumps

Aod Pumps: Repair it or Replace it?

“We are using Aod pumps side by side at our manufacturing facility to pump jelly type slurry wastewater and waste oil or a combination of that. These AOD pumps are costing us $1000 to $2000 a piece to rebuild. They provide poor performance and the energy costs are ridiculous. This is the 21st century, there has to be a better alternative!! What can Wastecorp offer? Tim K. - Everett, Washington

read morePulp and Paper Process Pumps and You

Pulp and paper processors, saw mills and carton companies have a challenge in finding the right pumping equipment for various parts of their processes. Mineral processing, log washing, fan pumps, effluent sumps and hot pond transfer are just some of the applications this industry faces. Operators often do not have all the information needed to select the right size and style of pumps needed for this variety of pumping needs around their facility.

read moreHow to Find New Diaphragms for an Old Diaphragm Pump

One of the frequent calls we hear from customers is that they either have an older diaphragm pump make or need replacement diaphragms for their newer diaphragm pump. Some genuine replacement parts are easier to find than others. The good news is that replacement diaphragms and other parts for almost any kind of diaphragm pump are available for pumps dating back as far as the 1940’s.

read moreDiaphragm Pump for Sewage Pumping

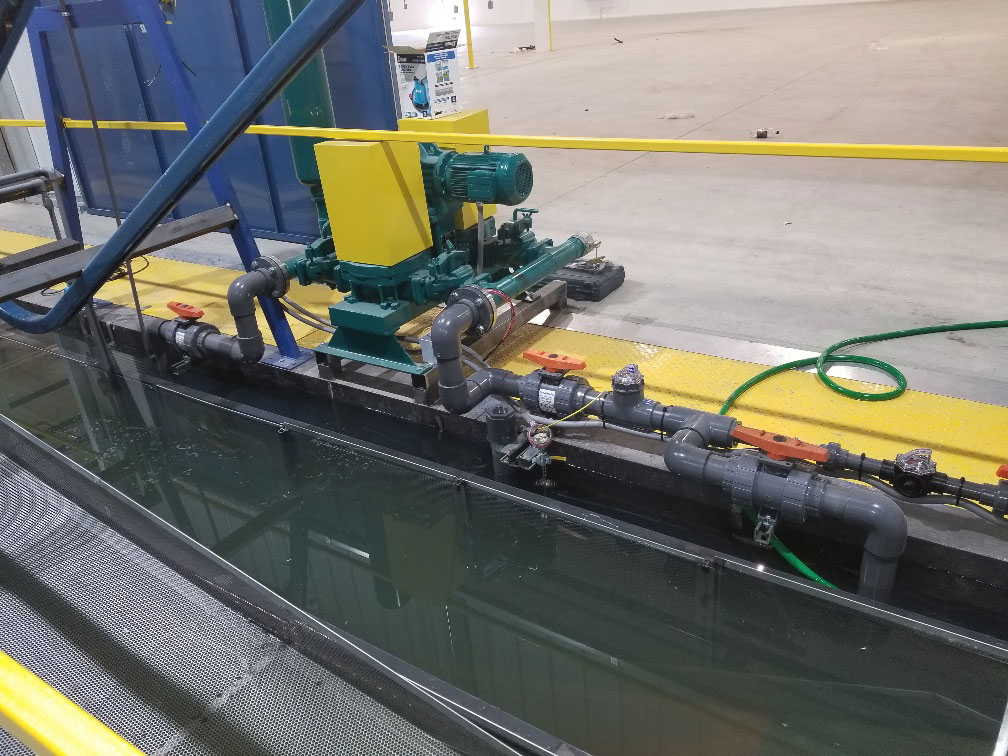

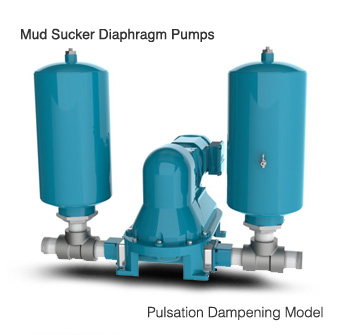

A WWTP just expanded and upgraded their pump facilities. The facility chose double diaphragm pumps to transfer sewage from digesters for secondary treatment. Project participants included Mud Sucker Diaphragm Pumps and pump manufacturer Wastecorp Pumps.

read moreTechnology Companies Using Mud Sucker Pumps

Wastecorp went right to work for HP designing and manufacturing two Mud Sucker 3B Series Professional diaphragm pumps to pump cooling tower condenser water, also called backwash pumps. The pumps were designed to continuously pump the condenser water between 60-80°F. In keeping with HP’s goal of exploring new strategies for reducing the environmental impact of next-generation data centers Wastecorp designed the mud Sucker with energy saving Siemens 3 phase motors and Sew Eurodrive gear boxes. Hp’s Mud Sucker’s were designed in an inline-piping configuration to save space at the facility. Santoprene diaphragms were included to help maximize component life with higher temperature liquids being constant.

read moreWaste Oil and Wastewater Pumps for the Natural Gas Industry

Pump Systems for Natural Gas and Power Generation

Honey wagon waste containment systems are used across a wide range of industries and have endless application

read moreIndustrial Wastewater Pumps – Case Study

Industrial companies looking to responsibly transfer waste oil and wastewater have found success with Wastecorp’s Mud Sucker 2FA Series diaphragm pumps. This

read morePumps: How to Maintain a Continuous Flow and Minimize Pulsation

With pumping applications, one of the challenges you face especially when pumping thinner liquids, is to maintain continuous flow without “jerking the hose” or disruptions in pump productivity. One of the consulting engineering firms we have worked with in California illustrates this point well:

read more