How to Pump Out of Waste Pits

Waste pits, sump pits, catch basin, overflow pit, pumping from waste containers are all pump applications that medium and large size facilities have to contend with in the food, manufacturing, chemicals, and septic management industries. Having the right pump and piping arrangement can help you get the job done properly.

We want to walk you through just a few of the critical factors you need to consider when planning your waste pit application.

What is the Sump Pit Depth That You Need to Pump Out Of?

The depth of your pit or suction line will determine what type of pump you need. For pits from 5’-10’ deep a diaphragm pump may work well for this application. The p

Vacuum Trailers For Off-Road Pump Applications

If you’re pumping out septic, waste trap grease, waste oil, jet fuel or other tough to pump fluids in offroad applications, like agricultural use, sandy beaches,

What You Didn’t Know About Double Disc Pumps

Can a Double Disc Pump Have Ball Valves?

Yes. In fact, ball valve technology is helping to usher in the next era of double disc style pumps. The ball valves help to break up solids and make pumping thicker municipal sewage easier. The ball valves also make it much easier to maintain the pump.

Waste Oil and Wastewater Pumps for the Natural Gas Industry

Honey wagon waste containment systems are used across a wide range of industries and have endless application uses. Waste containment systems are used to pump out wastewater, oil or septic waste from storage tanks, lagoons, barrels and more. The national gas industry requires honey wagons as well. From natural gas well process uses, wastewater containment and facilities management, portable waste containment systems play a valuable role in collecting wastewater and safely transporting is to an environmentally responsible dump station. With the advent of fracking, our customer base for waste containment systems in New York State, PA, Virginia and Kentucky has rapidly expanded. Dustin R, from Lexington, KY recently contacted Wastecorp about a new pump out system for his Natural gas company:

“We are looking for a mobile tank system to drain used oil tanks. The pump we would like to use is an air driven diaphra

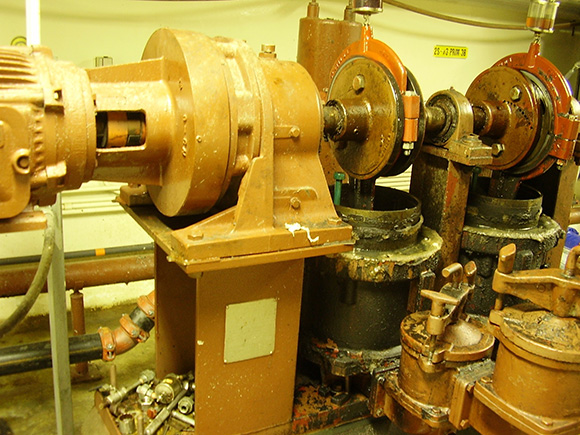

Pump Industry News: Replacing a Komline Sanderson Plunger Pump

Many of our wastewater treatment plant operators looking to upgrade their sewage pumps to the next generation plunger pumps have a wide set of options for a no piping change or little alternation to the existing set up. New sewage pumps can help make the facility more efficient and productive. This is available to all plunger pump customers including competing makes like Komline Sanderson* and Carter* Plunger Pump customers.

With a 3 hp motor, and 4″ discharge. Mike D. from Fort Worth Texas illustrates a number of pump questions we get from public utilities operators.

“I am looking to replace 2 Komline Sanderson KS-9 plunger pumps at my wastewater treatment facility. The pump characteristics are 140 GPM at 90 ft head. We get some grit in our sewage and we have a grinder on the suction lines of both pumps. Current pump is duplex plunger pump general arrangement. What is your equivalent of this pump? Do I have to make piping changes to my effluent lines? And what other pumps do you manufacture that we could consider installing? .” Thanks, Mike D. Fort Worth, Texas

Well Mike, you have a few different options when replacing those Komline Sanderson Plunger Pumps. As you know all plunger pumps are positive displacement pumps so you will have pulsation in your lines. Our air chambers which act as pulsation dampeners are on both the suction and the discharge which really helps with thinner

Airport Stormwater Pump Options

At airports around the world, storm water gets mixed with jet fuel during storms and must be properly pumped and treated before returning into the waterways. Most airports have stormwater pumping stations to prevent flood damage, protect the water supply and capture runoff before returning to canals levee’s

Primary Sludge Pumps at a WWTP

Primary sludge pumps are typically used in municipal Wastewater treatment facilities to transfer digested sewage and sludge. This is a broad pump category that encompasses positive displacement pumps to pump sludge in ranges usually up to about 500 GPM. The choices of pumps vary from double diaphragm pumps, plunger pumps, double disc pumps, rotary lobe pumps, progressive cavity pumps and more.

In todays pump marketplace, there are generally two schools that operators and consulting engineers follow when specifying primary sludge pumps. The first option is to install a more robust pump model with features like ball check technology to manage varying solids percentages or abrasive solids. These pumps typically cost a bit more to begin, but the spare parts costs are much lower down the road. Examples of such pumps are plunger pumps, double diaphragm pumps and double disc pumps.

Resolving Sewage Pump Problems at Smaller WWTP’s

How to resolve sewage pumping problems at smaller WWTP’s is a question on the minds of thousands of operators worldwide. These facilities pump municipal sewage, storm water, melting snow, road grit and so much more for smaller communities. While the gallons per day pumped may not be as high as urban sewage treatment plants, the need for reliable sludge pumps is just as great.

Wastecorp was contacted by a South New Jersey WWTP to provide upgraded sewage pumps to transfer wastewater, sludge and s