Diaphragm Pump for Sewage Pumping

If your pump project calls for primary sludge pumps under 220 GPM, the Mud Sucker Double Diaphragm pump is something you should consider for municipal sewage and industrial sludge pumping applications.

Case in point: A Northeast urban wastewater treatment plant upgrade and expansion recently

specified and installed two Mud Sucker 3B-EC-DD Series double diaphragm pumps with one and three quarter inch solids handling capabilities These Mud Sucker’s pump primar

Marinas Pump Outs, Campground Pump Outs and Commercial Marine Pump News

Wastecorp has released updated pump brochures and buyers guides for our marina, campground or commercial marine customers just in time for the height of the season. The new literature includes sample installations and a host of new products like honey wagons designed to help get these jobs done faster than ever before. You can download the brochures or request by mail.

Wastecorp has released updated pump brochures and buyers guides for our marina, campground or commercial marine customers just in time for the height of the season. The new literature includes sample installations and a host of new products like honey wagons designed to help get these jobs done faster than ever before. You can download the brochures or request by mail.

Marina Pumps

Our extensive marina pump buyers guide, highlights Wastecorp’s growing presence in the recreational marine pump out industry. Our pumps have been a hit with both small and large marinas for their ease of use and long life cycles. We’ve also included some great automated options for dockside pump out systems including complete control panels, remote controls and more.

View Marine Pump Products available in your area

Plunger Pump Sewage Transfer Pump in PA

For wastewater treatment facilities that are upgrading their sewage pumping equipment, getting the right pump technology to do the job is critical. For one thing,

Waste Oil and Wastewater Pumps for the Natural Gas Industry

Honey wagon waste containment systems are used across a wide range of industries and have endless application uses. Waste containment systems are used to pump out wastewater, oil or septic waste from storage tanks, lagoons, barrels and more. The national gas industry requires honey wagons as well. From natural gas well process uses, wastewater containment and facilities management, portable waste containment systems play a valuable role in collecting wastewater and safely transporting is to an environmentally responsible dump station. With the advent of fracking, our customer base for waste containment systems in New York State, PA, Virginia and Kentucky has rapidly expanded. Dustin R, from Lexington, KY recently contacted Wastecorp about a new pump out system for his Natural gas company:

“We are looking for a mobile tank system to drain used oil tanks. The pump we would like to use is an air driven dia

Fabricant de pompes industrielles

Wastecorp Pumps est la nouvelle génération de matériel de pompage industriel pour la manutention des boues et des solides, disponible pour les industries alimentaires,

Trash Pumps: Selecting The Right Pump

When looking for a trash pump for your rental, municipal, industrial or mining pump application, you will likely encounter dozens of manufacturers out there. The pump industry is certainly not short on selection. But here’s what you should know: sizing the right pump for your application can not only help you get the right pump, but may also prevent premature pump wear and maintenance down the road.

Wastecorp’s engine driven trash pumps take into account, the variety of needs in the trash pump marketplace. First, Wastecorp has divided the category into two

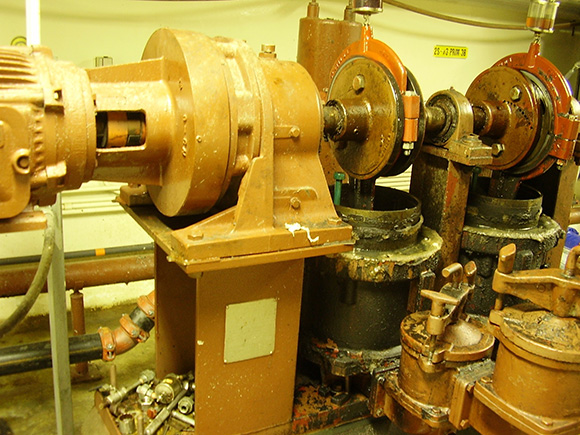

Pump Industry News: Replacing a Komline Sanderson Plunger Pump

Many of our wastewater treatment plant operators looking to upgrade their sewage pumps to the next generation plunger pumps have a wide set of options for a no piping change or little alternation to the existing set up. New sewage pumps can help make the facility more efficient and productive. This is available to all plunger pump customers including competing makes like Komline Sanderson* and Carter* Plunger Pump customers.

With a 3 hp motor, and 4″ discharge. Mike D. from Fort Worth Texas illustrates a number of pump questions we get from public utilities operators.

“I am looking to replace 2 Komline Sanderson KS-9 plunger pumps at my wastewater treatment facility. The pump characteristics are 140 GPM at 90 ft head. We get some grit in our sewage and we have a grinder on the suction lines of both pumps. Current pump is duplex plunger pump general arrangement. What is your equivalent of this pump? Do I have to make piping changes to my effluent lines? And what other pumps do you manufacture that we could consider installing? .” Thanks, Mike D. Fort Worth, Texas

Well Mike, you have a few different options when replacing those Komline Sanderson Plunger Pumps. As you know all plunger pumps are positive displacement pumps so you will have pulsation in your lines. Our air chambers which act as pulsation dampeners are on both the suction and the discharge which really helps with thinner

Updating Your Wastewater Pumping System

When it comes time to update your wastewater pump system especially for mobile applications you should know your options. There are a range of products available with components designed for your specific application. The photo you see left was sent by a multinational mining company who contacted Wastecorp to design a new fleet system to collect used machine oil and wastewater from various mining sites. The previous pump systems had been in service for over 30 years and the customer required an updated pump out system with added durability and pumping power. The customer also had height restrictions for pumping in a variety of mining facilities including shafts and waste ponds.

Wastecorp went to work and supplied the customer with quantity 10 read more

How to Change The Disc Assembly on A Double Disc Pump

The video below shows how to change the trunnion on a Sludge Pro double disc pump. As you can see most of the maintenance is done with the operator standing up and most components visible to the operator.

Safety First

Changing the disc assembly on a Sludge Pro double disc pump is a simple process which can usually be done within 30 minutes-45 minutes.

Airport Stormwater Pump Options

At airports around the world, storm water gets mixed with jet fuel during storms and must be properly pumped and treated before returning into the waterways. Most airports have stormwater pumping stations to prevent flood damage, protect the water supply and capture runoff before returning to canals levee’s