Pump out system for government specifications

Wastecorp has worked with many government agencies including the Department of Defense, Department of Homeland

Pump out system for government specifications

Wastecorp has worked with many government agencies including the Department of Defense, Department of Homeland

In a world of increasing water scarcity, wastewater management has become crucial to limiting the adverse effects of climate change and population growth. Purifying wastewater allows us to conserve [...]

You name the tank that needs to be pumped out and we have heard of at least a few customer applications that correspond with that tank. Underground septic tanks, lagoon transfer, transport truck tankers, locomotive tankers, waste pits and waste vegetable oil drums are among the most popular. What you have to keep in mind is that in most of these applications, you will need a pump that can easily maneuver in areas to access the discharge valve or at least some place where you can place the suction hose.

Do you need to adjust the speed of your pump’s electric motor, modulating the power being delivered? We’ve got good news; all Mud Sucker diaphragm pump models are now available with a variable frequency drive (VFD). VFD’s help to accommodate fluctuating demand by adjusting pump energy consumption and costs by adjusting the amount of power delivered to the motor for pumping specific tasks.

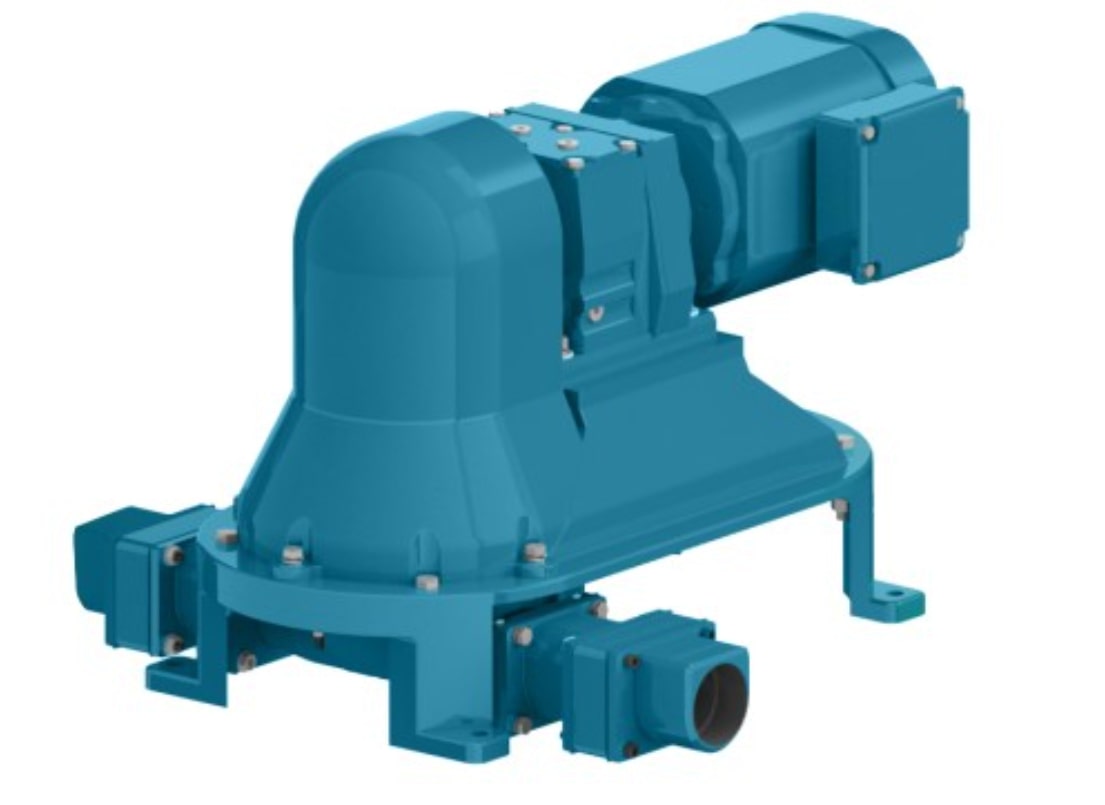

Getting the most of your honey wagon pump out system will help you maximize your day-to-day productivity. In the video above you will see how to use the honey wagon to pump both into and out of the tank with the same pump. You will also see how easy it is to change the direction of flow when needed.

When we hear about silt pumping applications it usually involves pumping from a mining site, fruit juice concentrate or dredging application. Often, job site operators have contained the silt-laden wastewater in either a holding tank or tote tank. Typically, the liquid waste must be treated or pumped to a larger containment area.

State-of-the art food processing facilities and the engineers who design them have a challenge in finding the right pumps and control panels to transfer process wastewater. This was the case for fast food restaurant chain White Castle’s brand new innovative processing center in Vandalia, Ohio USA. Wastecorp worked with White Castle, local contractor PAE and Associates (who specialize in Wastewater treatment plant construction) and

Personal waste containment systems or “honey wagons” as they are sometimes called in the pump industry have come along way in just the last few years. In response to the soaring costs of vac truck services, everyone from those needing septic pumping, waste oil pumping and used vegetable oil transfer have found an economical alternative in owning a personal waste containment systems.

Waste pits, sump pits, catch basin, overflow pit, pumping from waste containers are all pump applications that medium and large size facilities have to contend with in the food, manufacturing, chemicals, and septic management industries. Having the right pump and piping arrangement can help you get the job done properly.

No one can argue that having a simple diaphragm pump for farm and ranch applications can some times be a lifesaver and time saver. Whether you’re pumping manure, silt from a pond, fruit juice or vegetable matter and more,having a trusted pump by your side can mean the difference between having aconsistently reliable pump and one that is nothing but hassles or in need of repair. Troy from Sandusky Ohio, has been a farmer in the area for decades.Here’s part of the discussion we had with him about his pumping needs and some recommendations we made: